Operating principle at a glance:

Direct Pipe® in operation

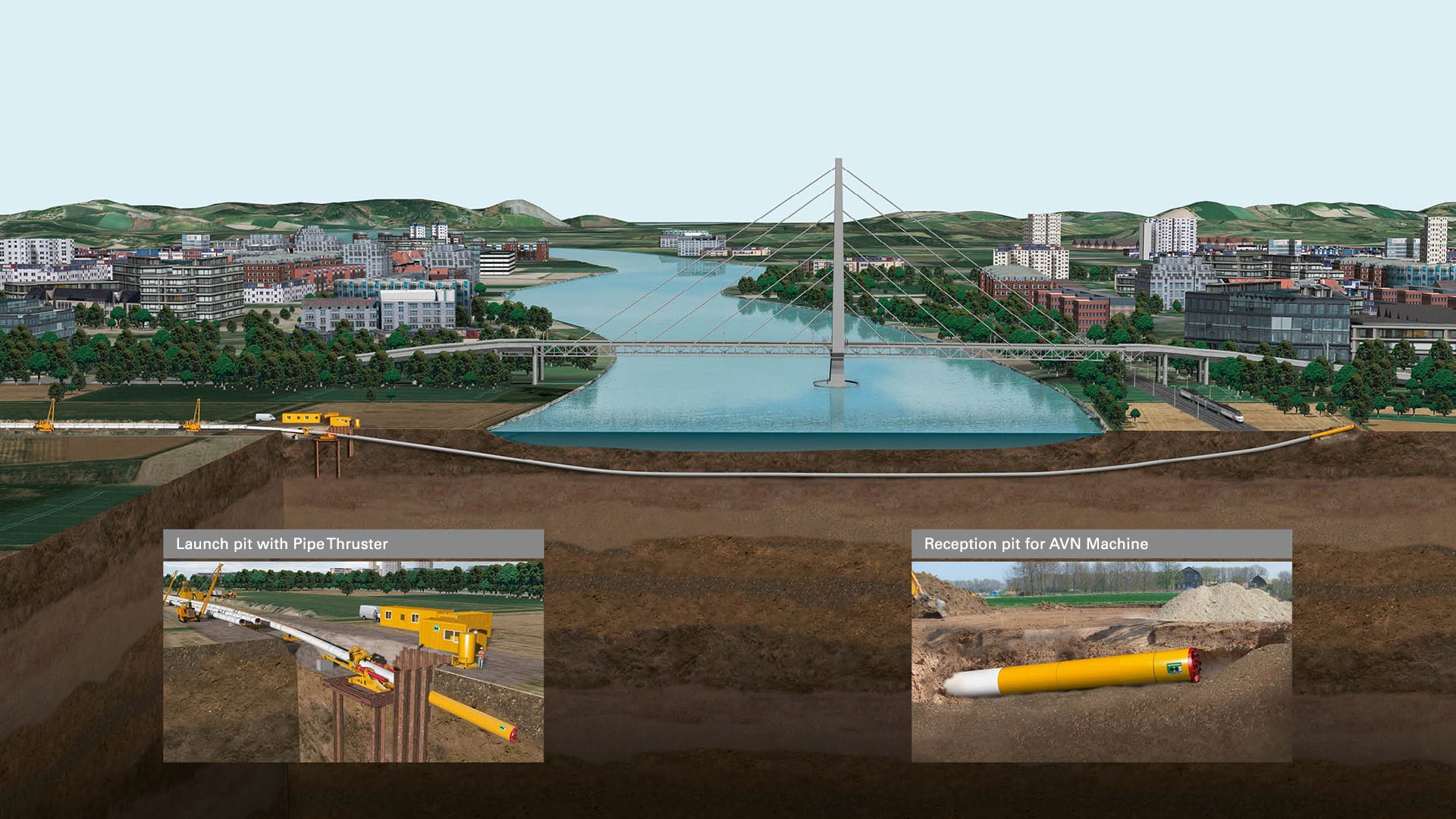

With the unique Direct Pipe® technology, Herrenknecht has opened up new possibilities for installing pipelines in every geology. This method combines the advantages of microtunnelling and HDD technology. In one step only, a prefabricated pipeline can be installed and the required borehole excavated at the same time. This allows speedy and highly economic installation of pipelines with lengths of more than 1,500 meters.

Two technologies cleverly combined

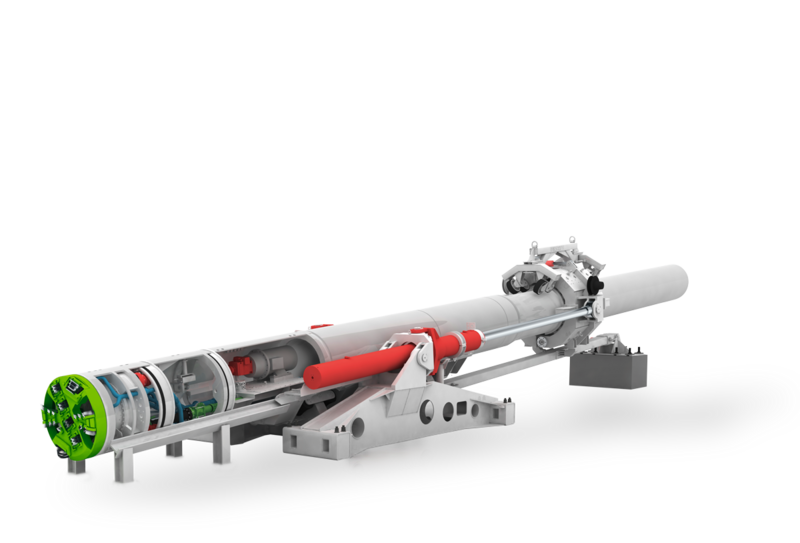

From the launch pit, the soil is excavated using a slurry-supported Herrenknecht Microtunnelling Machine (AVN). It pumps the excavated material through a slurry circuit inside the prefabricated pipeline, to a separation plant located aboveground. The pipeline, which is laid out on the surface on rollers and welded to the end of the microtunnelling machine, is pushed into the borehole at the same time as excavation takes place. The necessary thrust force is provided by the Pipe Thruster. It pushes the microtunnelling machine forward together with the pipeline – with a thrust force of up to 750 tonnes in increments of 5 meters. The push force is transferred to the pipeline through the Pipe Thruster’s clamping unit and then to the machine’s cutterhead. During excavation, the tunnel face can be controlled consistently and safely using slurry-supported tunnelling technology even in heterogeneous, water permeable soils. Uphill and downhill gradients as well as precise curve drives along the alignment can be managed with the gyro-based navigation system TUnIS Navigation MTGyro. Other navigation technologies can only be used to a limited extent due to the restricted visibility in pipelines.

The excavation tools of the AVN Machine remove the soil

Hydraulic support using slurry suspension

Hydraulic slurry circuit through slurry pipes installed inside the pipeline

Pipe Thruster advances the AVN Machine through the pipeline

Pipeline

Minimum foot print, maximum efficiency

The foot print of the equipment at the launch and reception points is very small with the Direct Pipe® method. Therefore, the technology can be implemented even in densely populated residential areas – simple, close-to-the-surface launch and reception pits are sufficient. It is no longer necessary to construct deep shafts. The microtunnelling machine is recovered in segments of approximately 3 meters in length after excavation is finished. In a final step, the supply and discharge lines are removed from the pipeline. The crossing is complete and the pipeline has been installed in one single step.

Functional principle

Attacking from one side only

With the Direct Pipe® method, the entire jobsite infrastructure, including the prefabricated pipeline, is located on one side of the crossing. Therefore, the expenses for logistics and the foot print requirements at the reception point are minimal. Hence, this technology is also ideal for constructing so called sea outfalls (landfalls) – where the pipeline is installed directly from the mainland out towards the open water. After reaching the planned distance, the machine is retrieved from the sea floor or lake bed.

Unique combination

By developing the Direct Pipe® method, Herrenknecht has achieved a breakthrough in pipeline installation. This combination of two already proven technologies has shown its value particularly in its high installation speeds. At the same time, the environment remains largely unaffected, mainly because the pipeline can be installed in one single step. Moreover, the method can be used practically in any ground condition.

Still got questions?

We are ready!