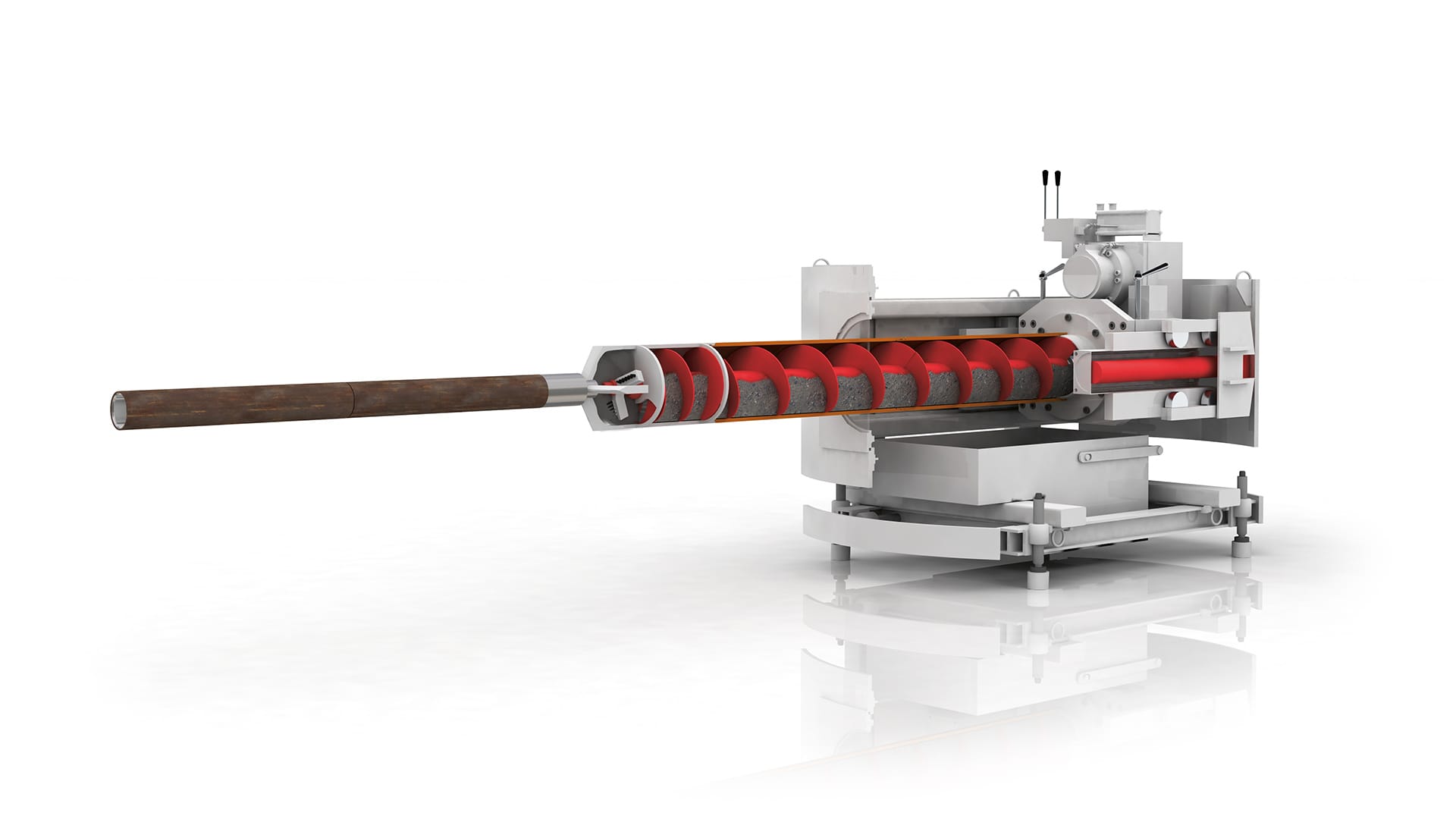

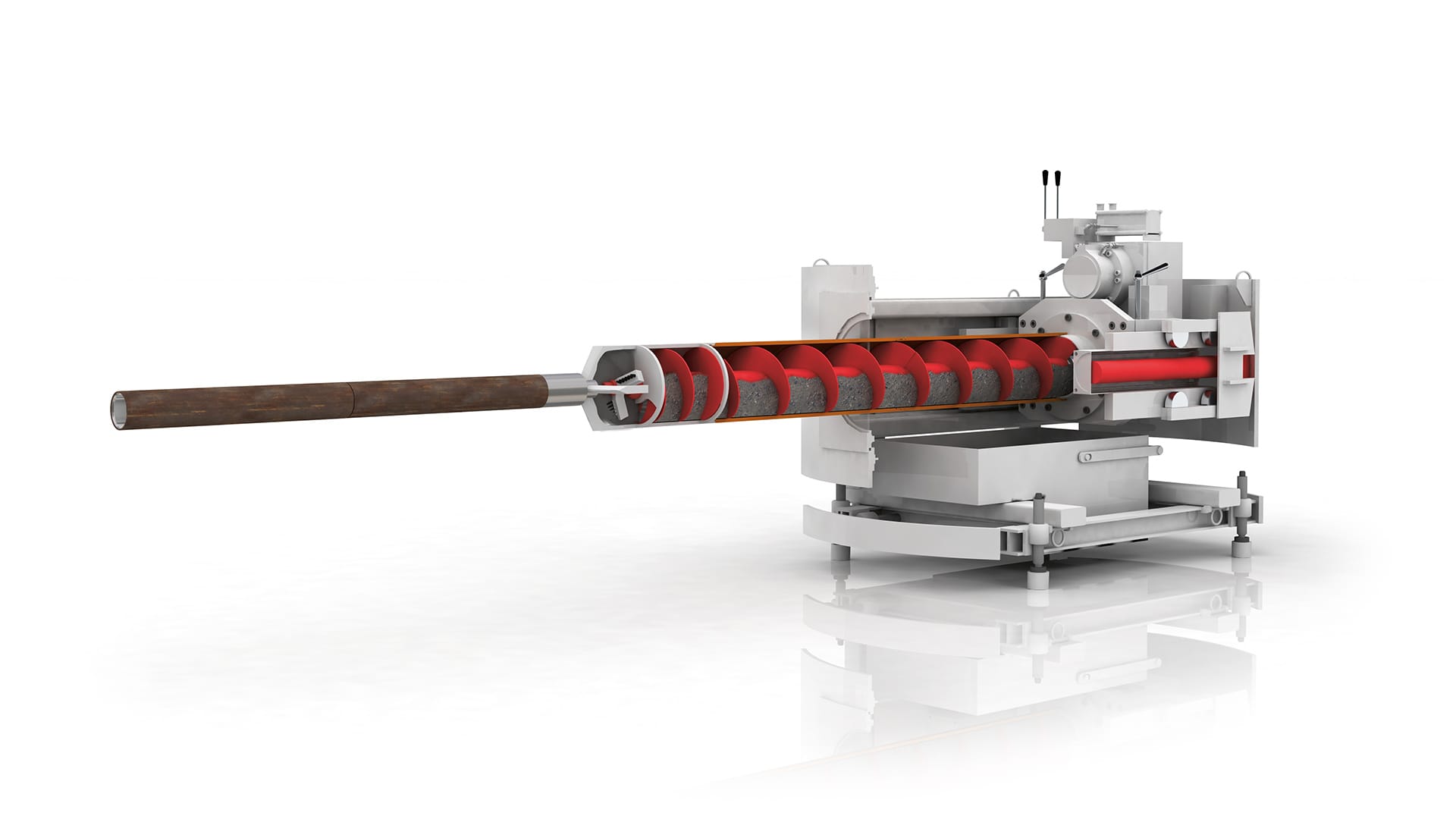

Operating principle at a glance:

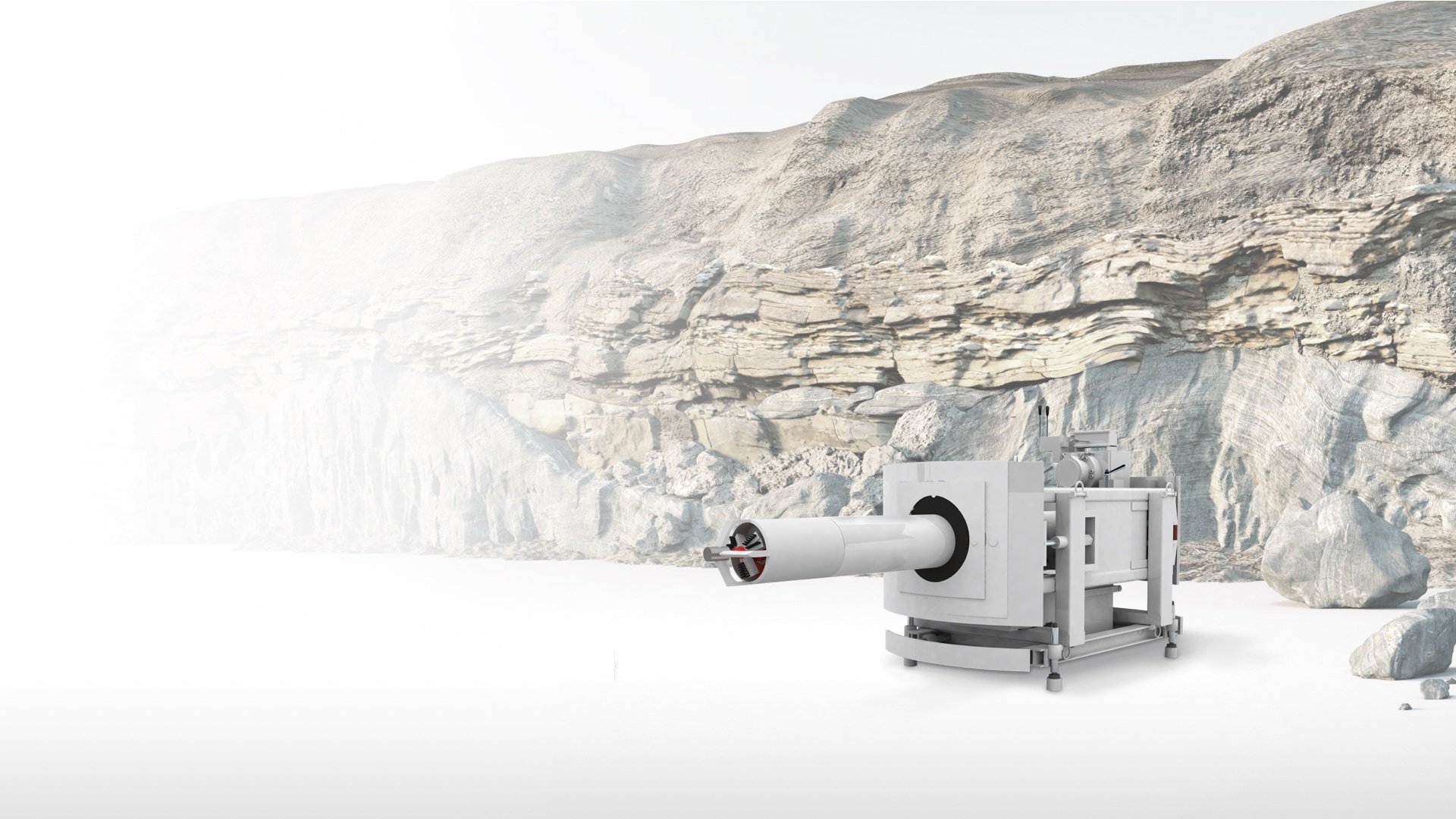

Auger Boring Machines in operation

Auger Boring Machines are used for the successful installation of sewage ducts and pipelines and for crossings beneath infrastructures. The boring machines offered by Herrenknecht in cooperation with Bohrtec GmbH stand out in comparison to conventional construction methods due to their technical, economic and ecological advantages. Their main range of application is underground pipe jackingwith comparatively small diameters, from 0.1 to 1.4 meters with drive lengths of up to 120 meters.

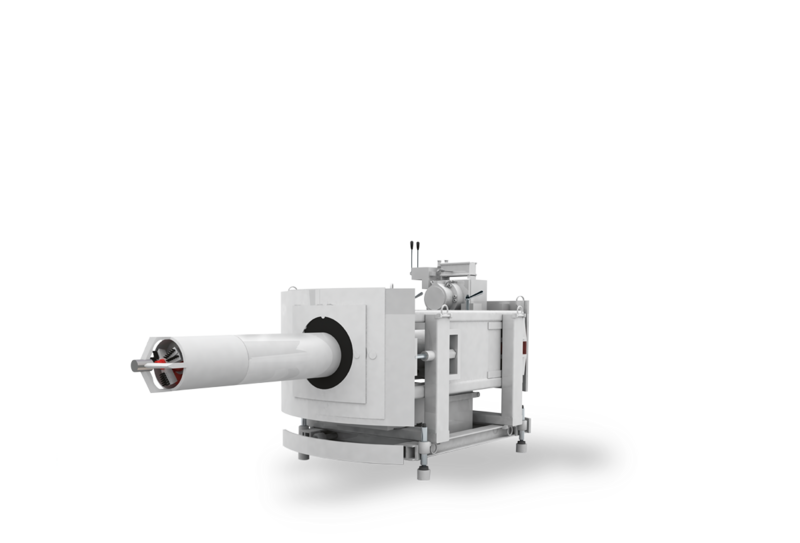

Simple basic principle, efficient tunnelling technology

Auger Boring Machines work according to the principle of soil transport by augers. They achieve high tunnelling performances in displaceable, dry soft soils. The principle is as clever as it is simple: augers situated inside a steel casing transfer the torque from the drive to the cutterhead. At the same time, they transport the excavated material from the tunnel face to the launch shaft. In this way, the drill is driven into the ground pipe by pipe. In the target shaft, the steel casings are recovered as the product pipes are installed.

Steering as required

The choice of steering methods depends to a great extent on the drive length and the required degree of drilling precision. For short drives, unguided machines are mostly used. The longer the individual pipe lengths, the more precise the drill. In cases of longer drives with higher precision, first of all a guided, soil-displacing pilot drill to the target shaft is carried out. The direction and inclination of the pilot drill are monitored precisely and permanently using an optical surveying system. Subsequently, different methods are available for enlarging the boreholes depending on the diameter.

Functional principle

The right technology for the job

Compact machines are used in inner-city areas and under confined jobsite conditions. If space constraints play a minor role on site, then so-called long frame machines are the ideal choice. Due to a modularly extendable frame design, they make it possible to jack steel pipes of up to 18 meters in length.

Various excavation tools remove the soil

Augers transport the excavated material to the launch shaft

The jacking and boring unit in the launch shaft pushes the cutterhead forward through the jacking pipes

Pipe jacking

Special developments for new applications

In non-displaceable soils or rock, steered pilot drills are not possible. For these special requirements, Bohrtec and Herrenknecht have worked together to develop the patented Front Steer technology. A drilling head excavates soil or rock up to a strength of 20 megapascal. The material is removed to the launch shaft using hollow stem augers with a continuous path for the optical surveying system. This enables millimeter-precise boreholes also in hard geologies and soft rock. For steel pipe jacking without hollow stem augers, an electronic water leveling system with an inclinometer is used as a surveying system. This means this technology can be used for every boring machine and with conventional augers. Solutions tailored specifically to customer and project needs complement this offer and extend the potential applications of this technology. Examples are the groundwater auger for drills of up to 3 meters below the groundwater level, the down-the-hole hammer for guided steel pipe jacking in hard rock, the retractable double-wall pilot rods for dead end drillings when installing drainage pipelines and the Hole Opener for pulling in plastic pipes.

Environmentally-friendly and proven worldwide

The Auger Boring Machines made by Bohrtec and Herrenknecht have already successfully proved their worth in hundreds of operations worldwide. Due to their simple tunnelling principle and expanded range of application, they make it possible to install pipelines and house connections quickly and safely at low cost and with minimum impact on the environment.

Still got questions?

We are ready!