All advantages at a glance:

-

Reserve force for the pipeline installation in HDD projects

-

Central technology component for the Direct Pipe® and Pipe Express® method

-

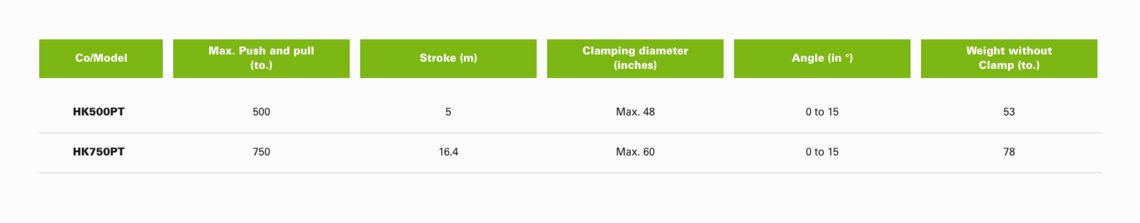

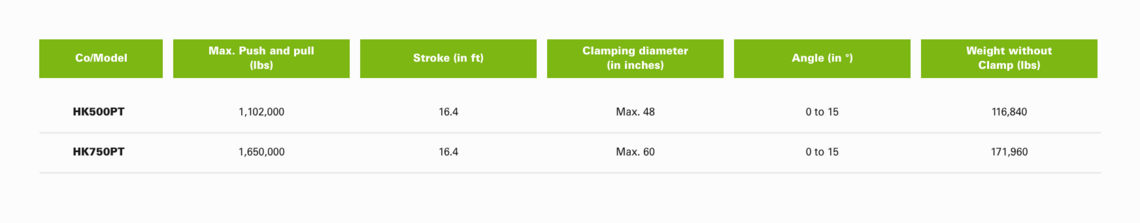

Max. thrust and pulling forces of up to 7,500 kN (750 t)

-

Recovery of stuck or damaged pipelines

-

Pipeline insertion into existing tunnels, pipes or boreholes

The Pipe Thruster in operation

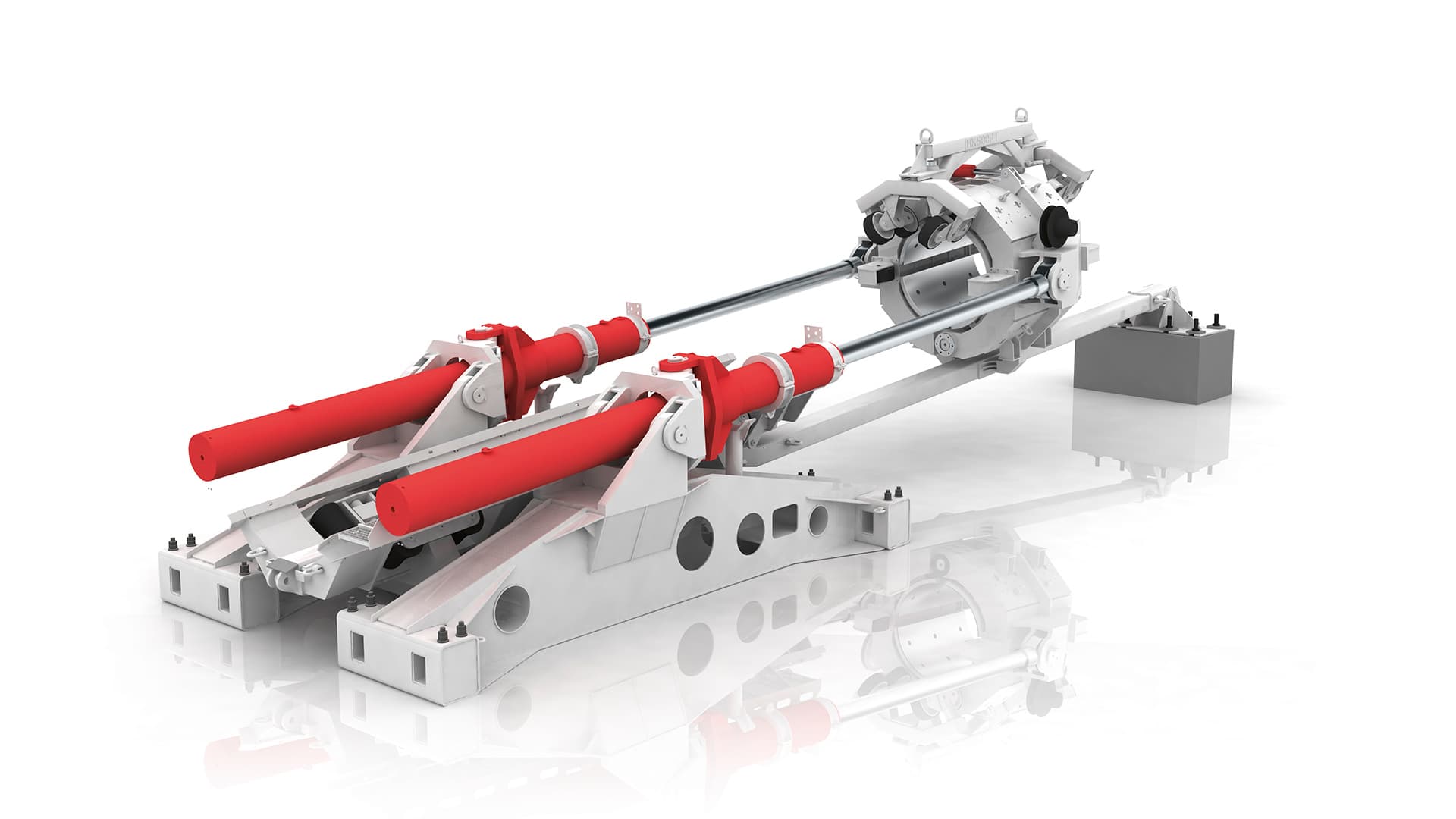

The Herrenknecht Pipe Thruster with its thrust and pulling forces of up to 750 tonnes plays a key role in the installation of pipelines. This powerful device, which can be used flexibly, increases the versatility of the HDD method towards even longer pipelines with large diameters or under difficult geological conditions. The Pipe Thruster can recover even jammed or defective pipelines. When using the Direct Pipe® or Pipe Express® method, the Pipe Thruster is always part of the system equipment.

Powerful when inserting the pipeline, gentle to the coating

The Pipe Thruster is installed at the pipe side and supports the HDD rig during pipeline installation. Additionally, it pushes the pipeline towards the rig side. Thus, the forces acting on the pipeline are applied better. A sure hand is required when thrusting the pipeline, as the pipeline coating must not be damaged. Two axially arranged hydraulic cylinders of the Pipe Thruster exert their variably adjustable force on the product pipe via a clamping unit. The clamping plates of the unit that are lined with special rubber have a sufficiently large contact surface to the pipe. In this way, they keep the contact pressure and the shear stress applied on the pipe low. More than 50 successful projects have proven that the coatings made of plastic (PP, PE, GRP, FBE) or of concrete are not damaged during operations. The annular clamping unit is opened on one side to install the product pipe. This means that the laborious “threading” of the pipeline can be avoided.

The application range of the Herrenknecht Pipe Thruster is extremely flexible. The usable pipeline diameter can be varied from 8 to 60 inches, simply by changing the clamping plates. Another advantage of the Pipe Thruster is that it exerts a maximum of 750 tonnes in the pull and thrust mode with the help of its extendible and retractable hydraulic cylinders, thus recovering stuck or damaged pipe strings. Other applications include the introduction of pipelines into existing tunnels or Sea Outfall projects, where gas and wastewater pipelines are pushed from land towards the sea using the Herrenknecht Pipe Thruster. This makes cost- and time-consuming offshore drilling facilities unnecessary.

Still got questions?

We are ready!