Multi-mode TBMs in operation

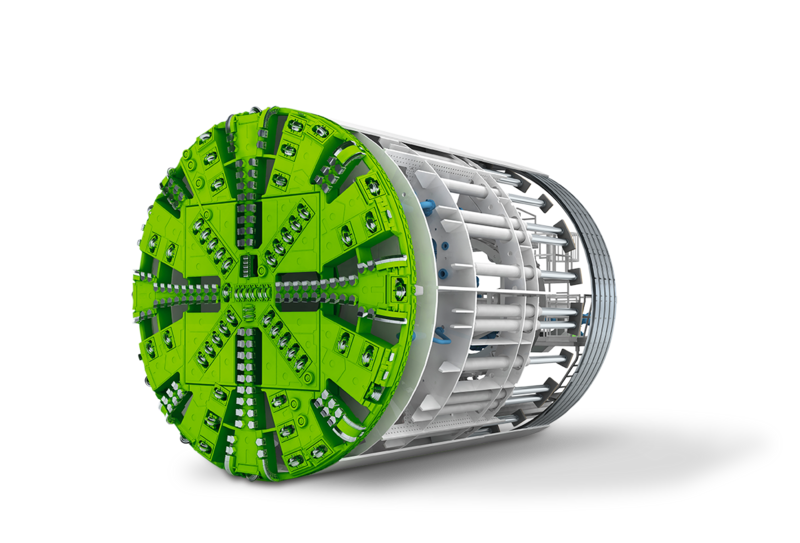

Classic tunnelling shields can reach their technical or economic limits with their specific method when they have to drive through highly variable geologies. Along one tunnel alignment to be excavated, the variable ground can change from stable rock to soft water-bearing ground and vice versa, for example, on longer sections. Such alignments pose the most demanding challenges in tunnel construction. Herrenknecht has developed Multi-mode TBMs for cases like this, ensuring optimum safety and flexibility during the entire tunnelling process. These machines are flexibly designed in terms of support and excavation methods. The tunnelling mode can be adapted to changing ground, requiring relatively short conversion times and incurring only low costs. This means that even tunnels with extremely varying geological and hydrogeological conditions can be constructed safely and cost-effectively using the innovative Multi-mode TBM made by Herrenknecht.

One basic idea, two concepts

In mechanized tunnelling there are basically three different shield types: Open-face Shields, Earth Pressure Balance Shields and Slurry Shields. Each of these proven methods has advantages in its special range of application. Technological advances have also enhanced the respective geological range of implementation over the past years. The aim is to use the optimum machine technology for the given geology, thus increasing project efficiency.

Many tunnel alignments lead through highly changeable ground conditions where classical methods come up against their technical or economic limits. For these special cases, Herrenknecht engineers have developed the Multi-mode TBM. The basic concept makes it possible to change between slurry support, earth pressure support and open mode within one tunnel alignment, by undertaking a range of conversions. In general, two design variants are possible.

- Multi-mode TBM with a modular basic structure. The tunnelling method is changed in the tunnel by extensive modifications to individual components.

- Multi-mode TBM with components allowing for several tunnelling methods, which are all integrated into the machine. The tunnelling mode can be changed in relatively short times and at relatively low cost. However, these machines have a considerably more complex technical design.

1. Combination of EPB and Open-face TBM

EPB Shields with screw conveyor in the invert section can be driven in the conventional closed EPB mode and also in the open mode. The excavation chamber and screw are only partly filled in this case. In this mode, no active support pressure against the tunnel face can be built up, and the screw conveyor is used only for removing the excavated material. Alternatively, a belt conveyor with a retractable muck ring can be installed in the center. This requires additional conversion measures at the cutterhead, and the screw conveyor is partly retracted in the open tunnelling mode. The combination of EPB Shield and Open-face TBM can be designed with a modular basic structure and as a version with parallel screw and center belt conveyor.

2. Combination of Open-face and Slurry TBM

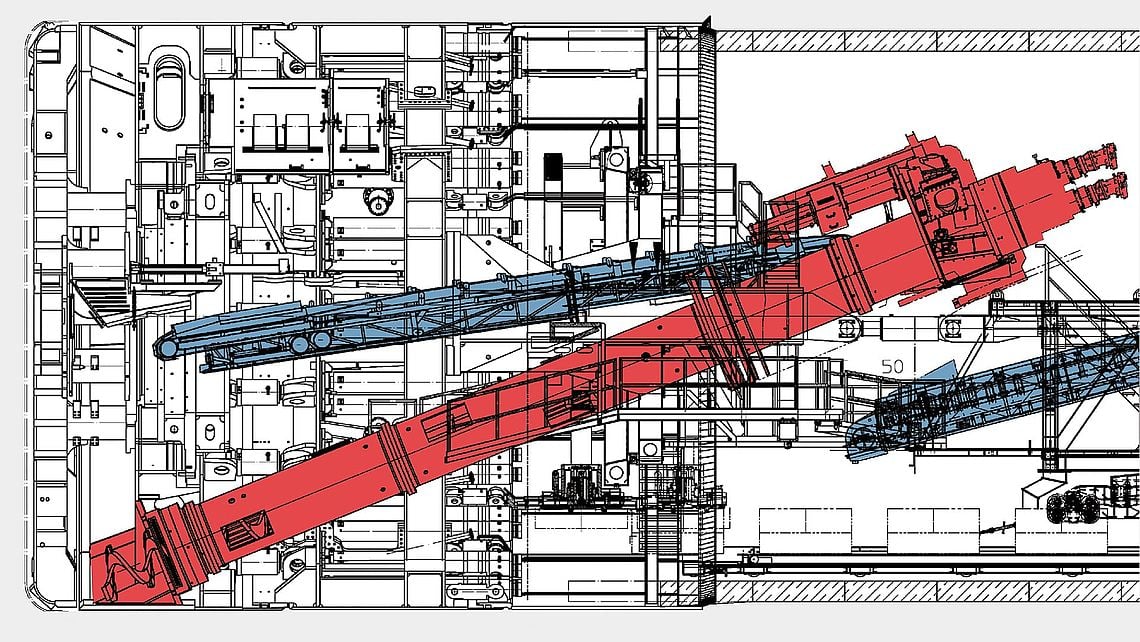

Multi-mode TBMs with open and slurry-supported mode have been used successfully in many projects. The greatest challenge when changing the tunnelling mode is to deal with the different ways of removing the excavated material. While the slurry-supported shield has a slurry circuit installed, in the open mode the material is removed using a center belt conveyor with retractable muck ring. This means that both conveying systems must be installed on the TBM and the back-up system in such a combination. Modular and integrated machine concept solutions are available.

3. Combination of EPB and Slurry TBM

Both modes of this combination work with a closed pressure system to actively support the tunnel face. The main differences consist in the composition and characteristics of the support medium, the conveying of the excavated material and the excavation chamber design. For large machine diameters of more than 9 meters, parallel installation of screw conveyor and slurry circuit in the invert section of the excavation chamber is possible. This is not the case for smaller diameters, which means that changing the tunnelling mode requires time and incurs costs. This is particularly true if an additional stone crusher is needed in front of the slurry circuit intake screen. That is why a combi¬nation of EPB and slurry shield is used only if specific project conditions justify these great efforts.

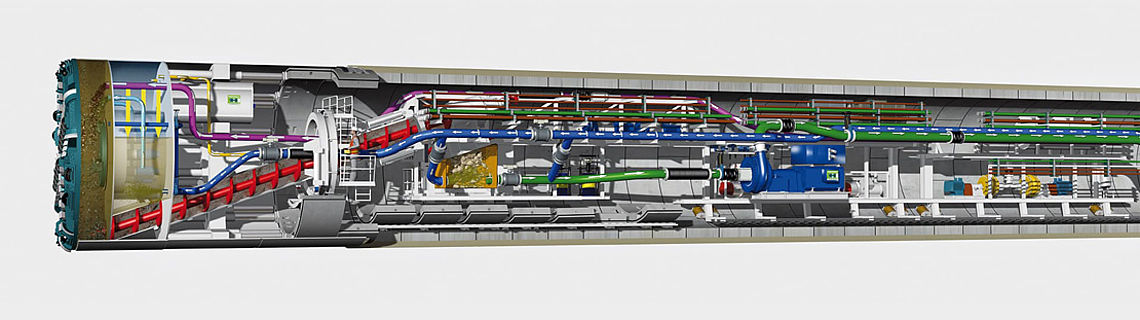

The special case of the TBM Variable Density®

A Multi-mode TBM with EPB and slurry-supported mode is the most complex form of a convertible machine so its use is only cost effective in very special cases. For this reason, Herrenknecht has developed the Variable Density TBM which applies a totally unique tunnelling technology. It combines the advantages of both methods in one machine. Without major mechanical modifications, the machine can switch between four different tunnelling modes directly in the tunnel. This means that geological and hydrogeological changes along the alignment can be managed with extreme flexibility.

The unique Variable Density technology from Herrenknecht is the all-round tunnelling technology for soft ground.

The excavated material is removed from the pressurized excavation chamber through a screw conveyor both in the earth pressure and in the slurry mode. Depending on the mode used, the support pressure is controlled via the screw conveyor speed and advance rate or using slurry that is automatically controlled by an air cushion. The submerged wall opening is replaced by communicating pipes. In EPB mode, the screw conveyor drops the excavated material onto a belt conveyor. An additional slurryfier box at the end of the screw conveyor makes it possible to drive the TBM with a hydraulic slurry circuit in slurry mode. In the latter case, either a normal bentonite suspension or a high-density suspension can be used.

This makes the range of application of the Variable Density TBM even larger and makes the machine the all-rounder for loose soils of all kinds.

Unique technology for very demanding underground missions

Demanding, often changing ground conditions along one tunnel alignment require new, innovative tunnelling technologies. Multi-mode TBMs from Herrenknecht meet these high requirements due to a flexibly designed machine concept. They are used wherever conventional shields come up against their technical and economic limits. Multi-mode TBMs are able to produce tunnels safely and cost-efficiently, even in extremely changeable ground conditions. Exactly where they are needed.

Still got questions?

We are ready!