Operating principle at a glance:

Partial-face Excavation Machines in operation

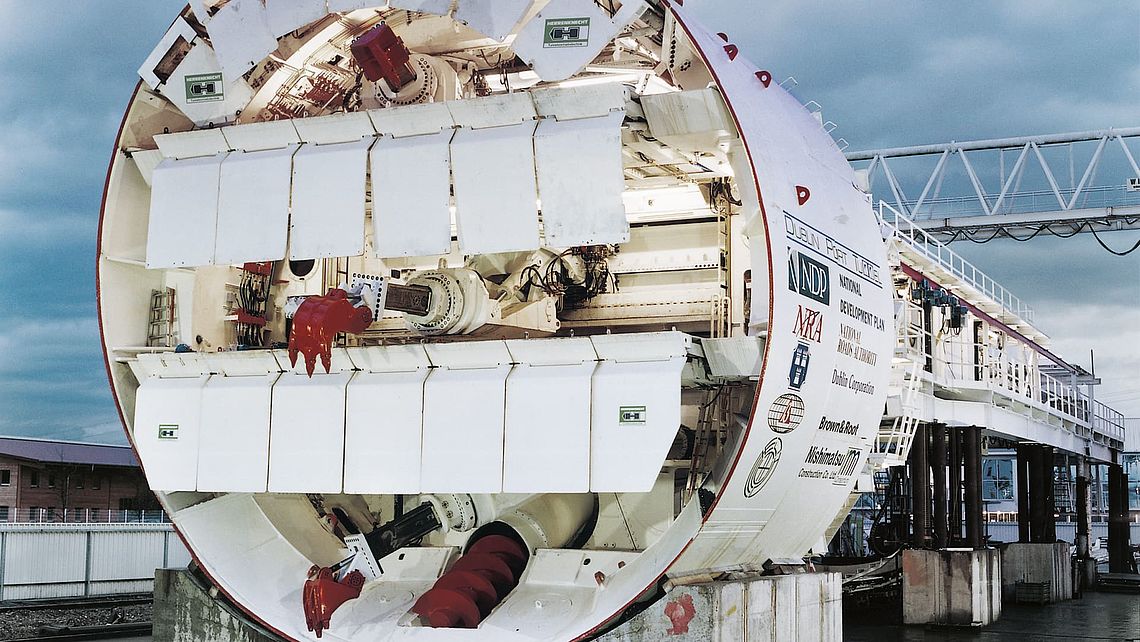

Partial-face Excavation Machines made by Herrenknecht are an economically interesting solution in homogeneous and almost stable grounds with little or no groundwater. This tunnelling technology can be easily adapted to changing geological conditions both in loose soils and in hard rock due to its strikingly simple design.

One machine, two excavation methods

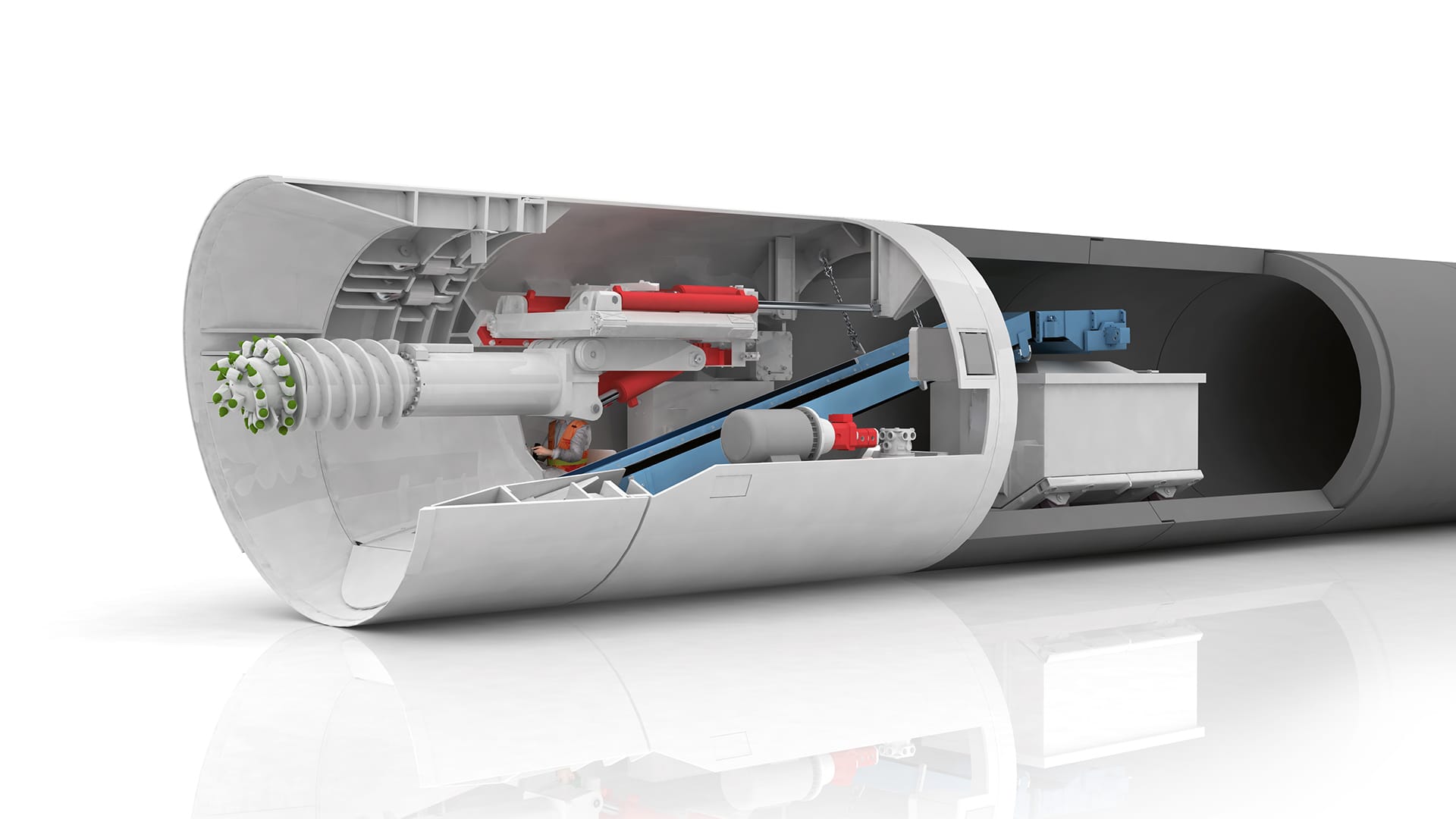

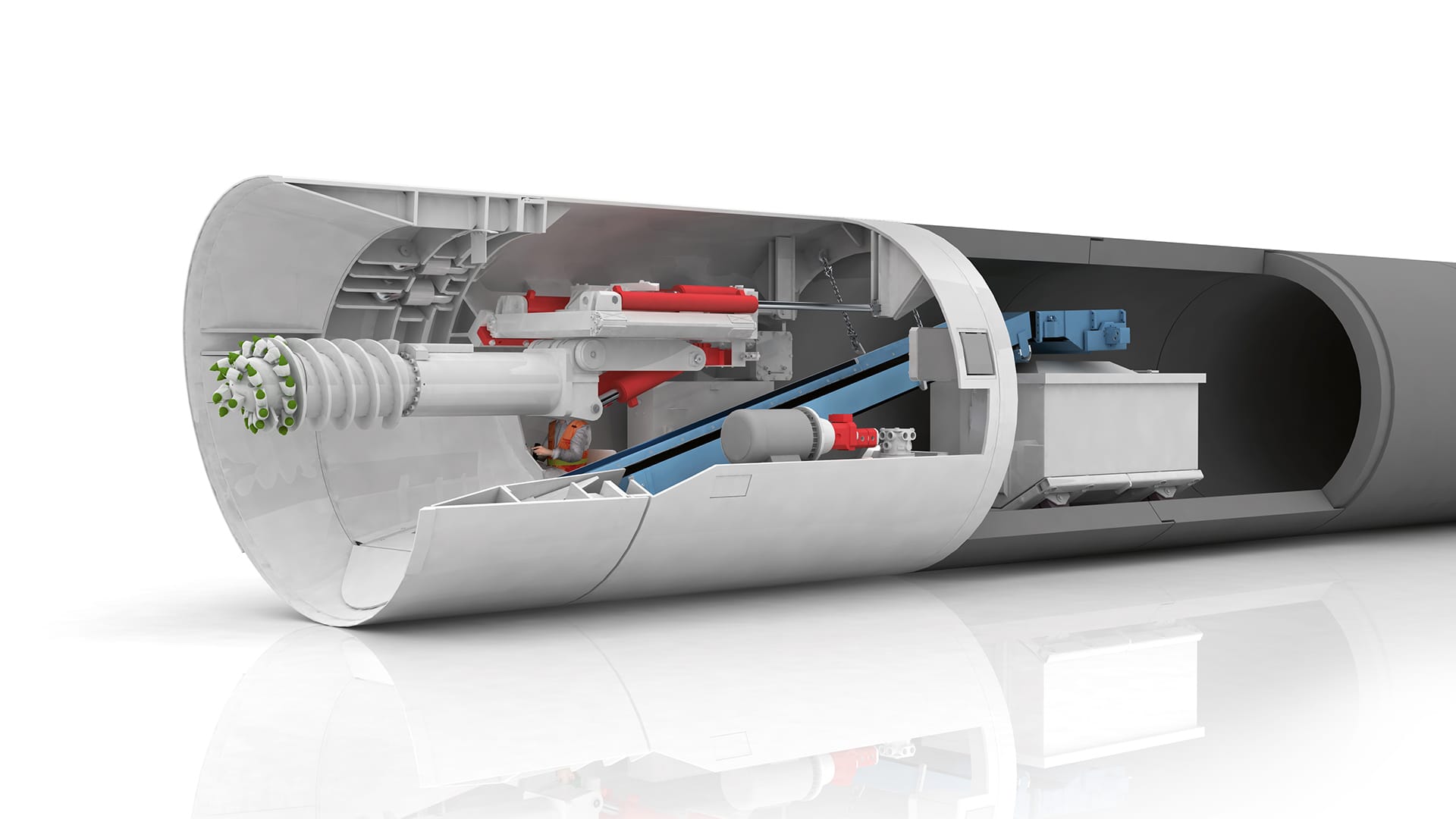

Herrenknecht shields with partial-face excavation can excavate the soil with two different cutting tools. In loose soils, the excavator has proved its great value hundreds of times. The universal excavator boom is equipped with a shovel, a ripper tooth or a hydraulic jackhammer – depending on the soil conditions. Roadheader booms are used in harder rock with uniaxial compressive strengths of up to 80 megapascal. Both boom technologies allow quick and easy replacement of the worn tools. The excavated material is transported by belt conveyors or chain conveyors to the conveying system in the back. The application range of Partial-face Excavation Machines starts at around 2 meters, as it is necessary to access the tunnel. Tunnelling operations with diameters of more than 10 meters can be carried out cost effectively using additional support measures or grout injections to improve the ground.

Functional principle

Direct visual contact with the geology

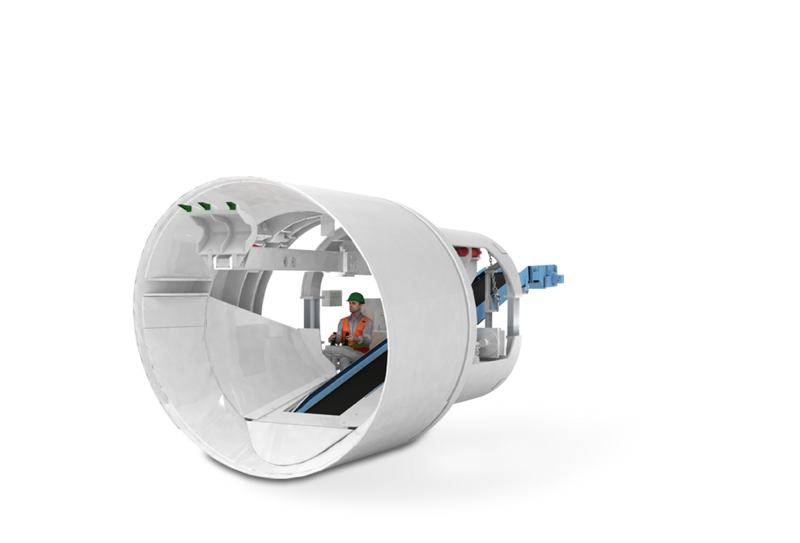

One advantage of Partial-face Excavation Machines is that the workplace of the operator is just a few meters away from the open tunnel face. This makes it possible to control excavation precisely, react swiftly to changes in the ground and take appropriate measures if necessary. One example is the excavation and removal of large boulders or obstructions without having to create additional shafts. Direct visual contact with the geology is also an advantage for the steering process. In pipe jacking, the machine is controlled using steering cylinders and an articulation joint in the front section of the shield. With larger diameters and during segmental lining, the machine is steered via the main thrust cylinders in the same way as closed-shield machines.

Always on the safe side

Partial-face Excavation Machines are open tunnelling shields that do not have a closed system for pressure balance at the tunnel face to provide soil and groundwater support. Therefore, various mechanical methods are used to ensure adequate support and to protect the machine against groundwater inflow.

Almost all Partial-face Excavation Machines are designed as forward shields. The rim of the shield and its leading edge are extended forward at the crown section in the direction of drive. Thus the repose angle of the surrounding ground is corrected to ensure controlled removal of the excavated material. At the same time, no soil can break away from the top and settlement can be avoided. The entire shield can also be designed as a so-called poling plate system with the shield divided into several plates which can be extended individually towards the front. In changing ground conditions this means that the natural repose angle can be adjusted continuously. Larger diameter machines are equipped with one or more horizontal support platforms, which also control the repose angle of the geology. This type of open-face machine allows installation and operation of several excavation tools at a time on different transverse platforms – increasing excavation speed. Often, hydraulically extendible or telescopic face plates are also installed – especially in the crown. They support the tunnel face mechanically and are partially retracted during excavation.

In partially water-bearing soils, the Partial-face Excavation Machines and a part of the tunnel can be supplied with compressed air through an airlock system. This prevents intrusion of groundwater. The operator’s workplace is located in the protected pressurized section. A compressed air system consisting of two control loops continuously verifies the required pressure and performs the corresponding adjustment, if necessary.

Easily and safely to breakthrough

Partial-face Excavation Machines made by Herrenknecht are directly controllable, easy to handle as well as easily convertible and can be used in different geological conditions. The machines achieve good and stable advance rates in suitable grounds – at attractive investment conditions. Therefore, they can be an ideal solution for constructing tunnels, both in pipe jacking and segmental lining. Moreover, the exterior diameter of the Partial-face Excavation Machines can be extended flexibly using an upsize kit. They can therefore be used successfully in several projects with varying diameters.

Still got questions?

We are ready!