OFD in operation

The number of offshore installations for expanding the use of renewable energy and the construction of coastal infrastructure has grown rapidly in recent years. As a result, demand for economical and environmentally friendly installation technologies for offshore foundations has increased. These are needed for wind turbines, substations, tidal power plants and bridges as well as for harbor infrastructure such as quay walls, breakwaters and jetties.

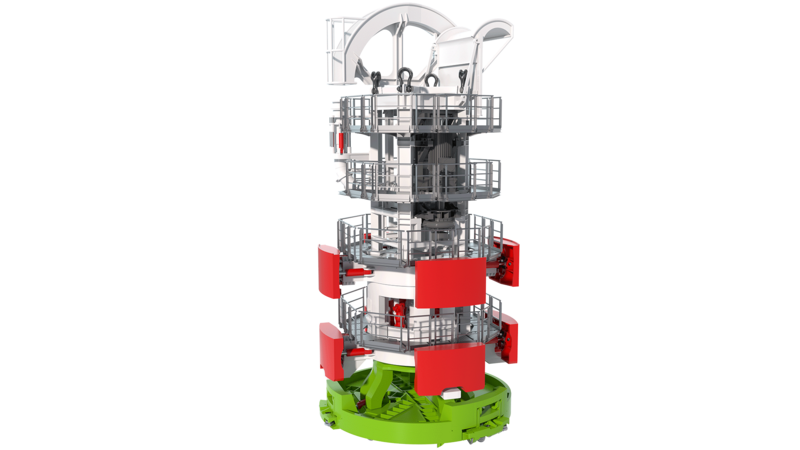

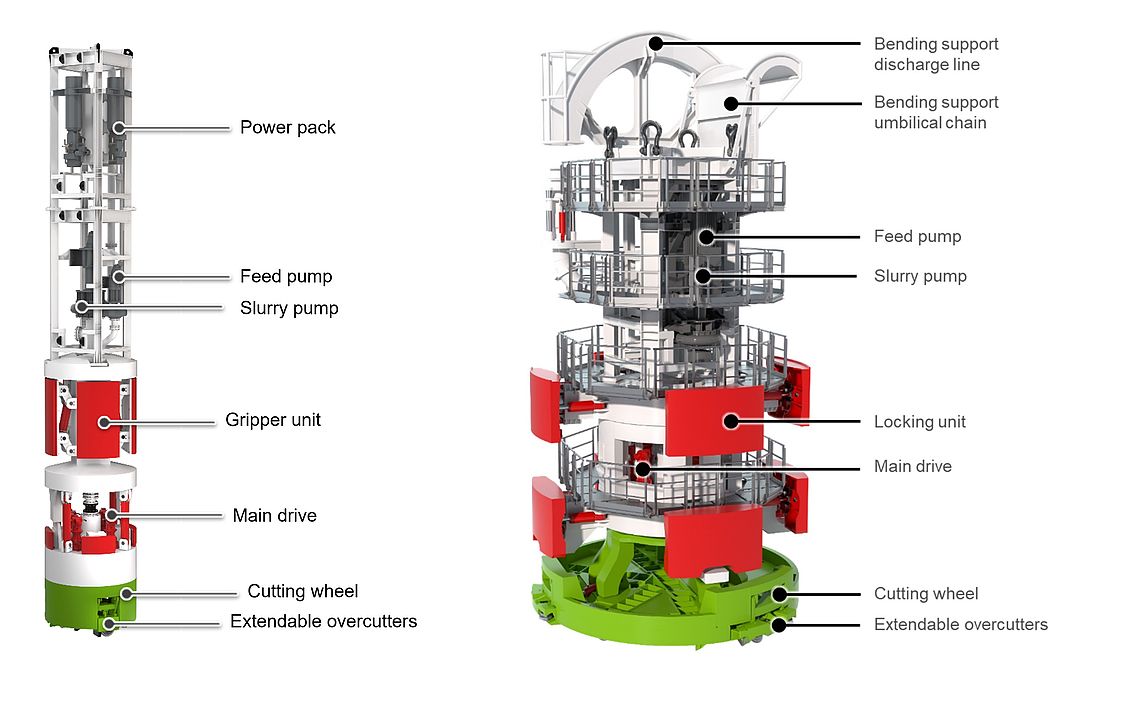

The Herrenknecht OFD technology uses a full-face drilling concept and a down drive behind the cutterhead to overcome the limits of conventional methods. This applies in particular to difficult ground conditions unsuitable for pile driving and where established pile driving methods would cause critical noise emissions. As seawater is used to transport the excavated soil to the surface through a slurry circuit, a separation plant on the surface is not required.

The drilling process

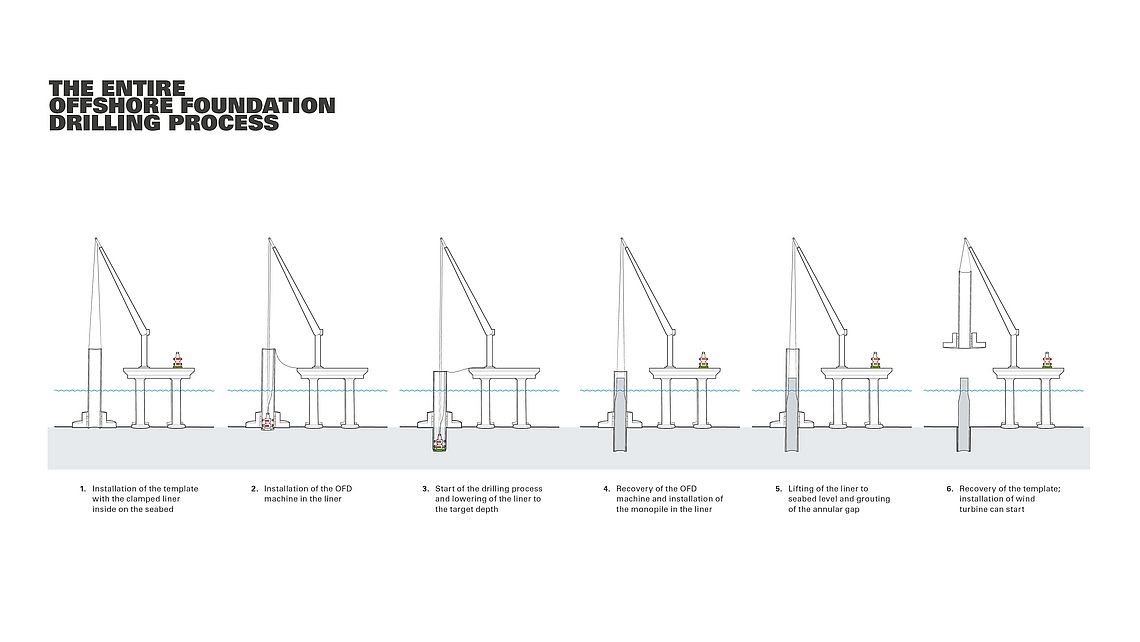

In a first step, the foundation pile or casing is installed vertically at the drilling location. A pile gripping unit or a lowering system holds the foundation pile or casing in place to safely control the subsequent drilling process. The drilling process begins after the OFD machine has been lowered into the foundation pile or casing. There it is fixed at drilling level with the help of a locking system to keep the drilling machine in its vertical position.

In the next step, the overcutters of the cutting wheel are extended underneath the foundation pile or casing for underreaming. The drilling process begins with the activation of the slurry circuit needed to transport the excavated/loosened soil to the surface. At the same time, the cutting wheel starts to rotate. All supply lines as well as data cables and the discharge line are permanently connected to the machine.

Depending on the installation method, the vertical advance force is provided e.g. by a lowering system or by using the force of gravity. The lowering of the foundation pile or the casing occurs simultaneously with the advance of theHerrenknecht OFD machine. The lowering speed is controlled by the drilling operator. Hydraulic cylinders measure the downforce on the cutting wheel.

When the final depth is reached, the overcutters are folded in and the locking system is disengaged. The machine is attached to the crane on the surface, smoothly lifted out of the foundation pile or casing and placed into the seafastening system on the platform structure.

OFD for wind turbine foundations

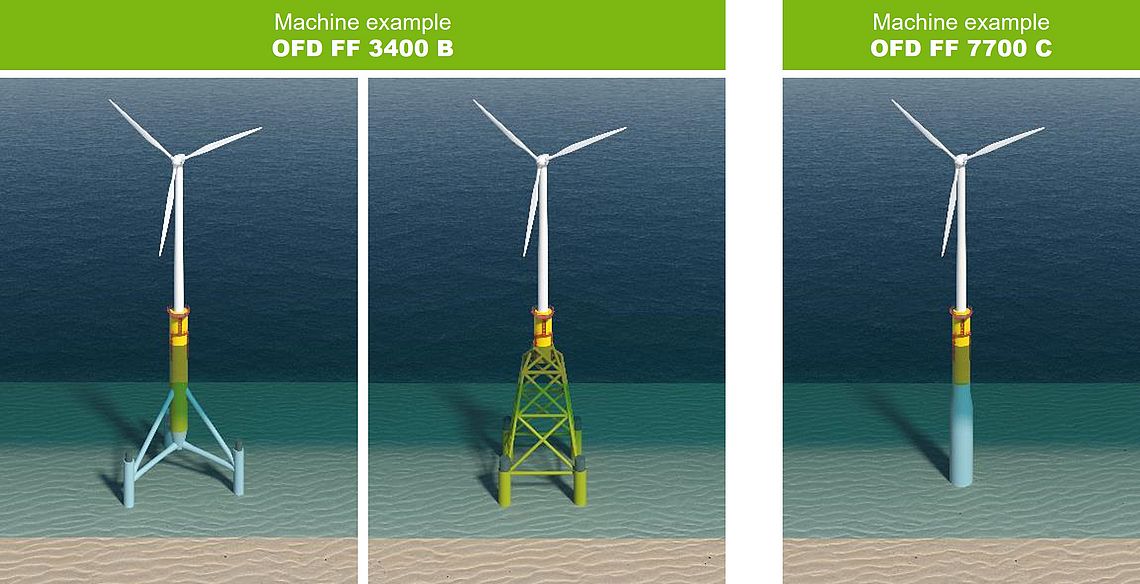

The Herrenknecht OFD technology was developed primarily for offshore foundation drilling for various types of foundation structures for wind turbines. While the small diameter OFD machine (e.g. OFD FF 3400 B) can cover pin pile foundations for jackets and tripods, the larger diameter OFD machine is mainly designed for the installation of large monopiles.

Offshore Foundation Drilling for smaller diameter pin pile foundations (left) and for larger diameter monopiles

Installation of foundation piles

The OFD machine can be used to install a foundation pile either directly in the seabed or in a two-stage process initially using a temporary casing. In the first case, the foundation pile must have a constant diameter through which the OFD machine can be recovered. In the second case, a temporary casing is used for the drilling process. The final foundation pile, e.g. a (conical) monopile, is inserted into the casing after the Herrenknecht OFD machine has reached the target depth and has been recovered and placed in a seafastening system on board the platform structure.

Future prospects

OFD Offshore Foundation Drilling by Herrenknecht is a mechanized solution that increases the feasibility of offshore projects requiring deep foundations or anchor points. New project sites will be explored in future, in particular where soil conditions, water depths and currents have been limiting parameters in the past. Environmental considerations and associated regulatory limits will continue to drive the development and use of mechanized construction methods for offshore foundations, nearshore and offshore, for both renewable energy and infrastructure projects.

Still got questions?

We are ready!