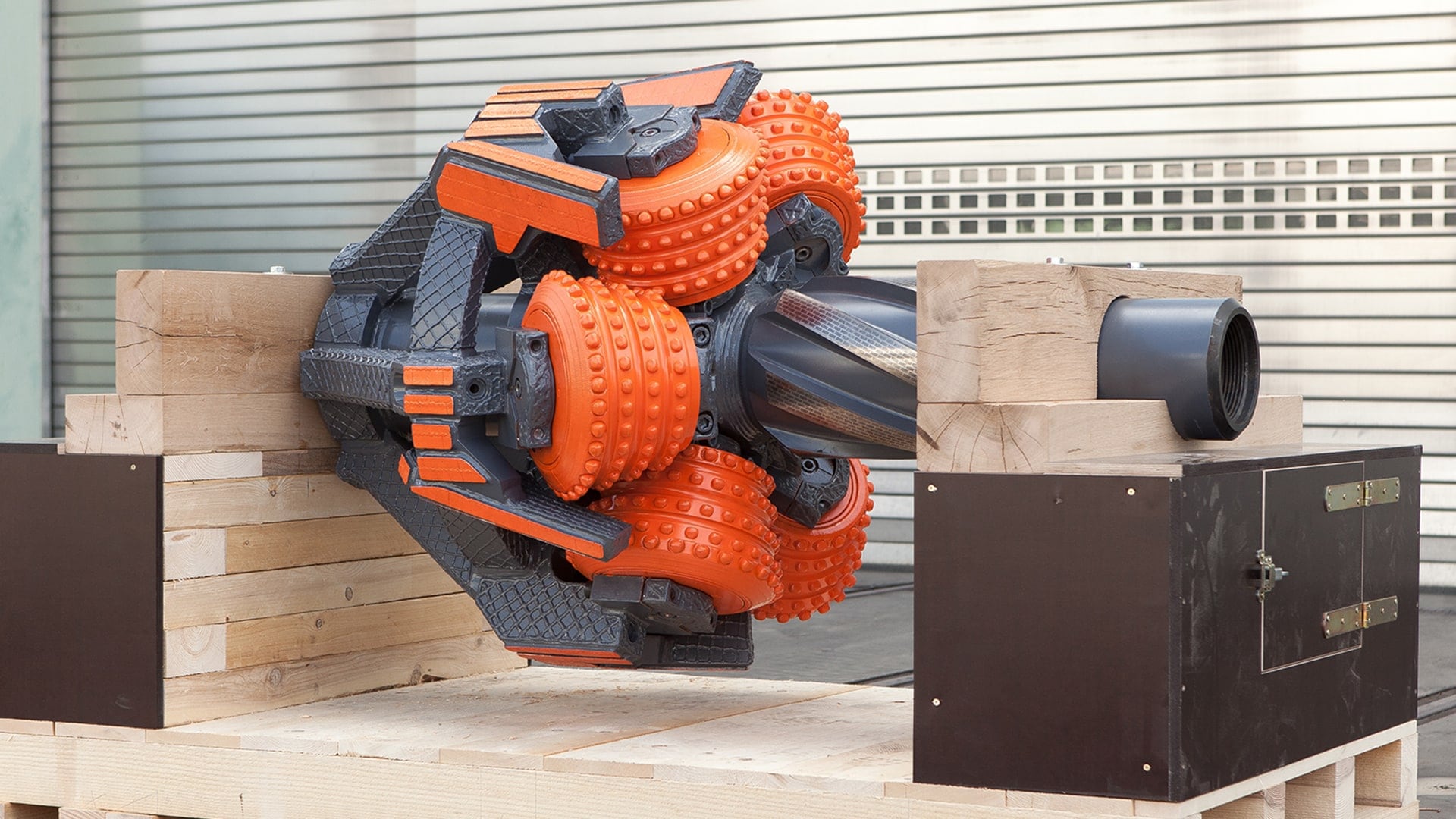

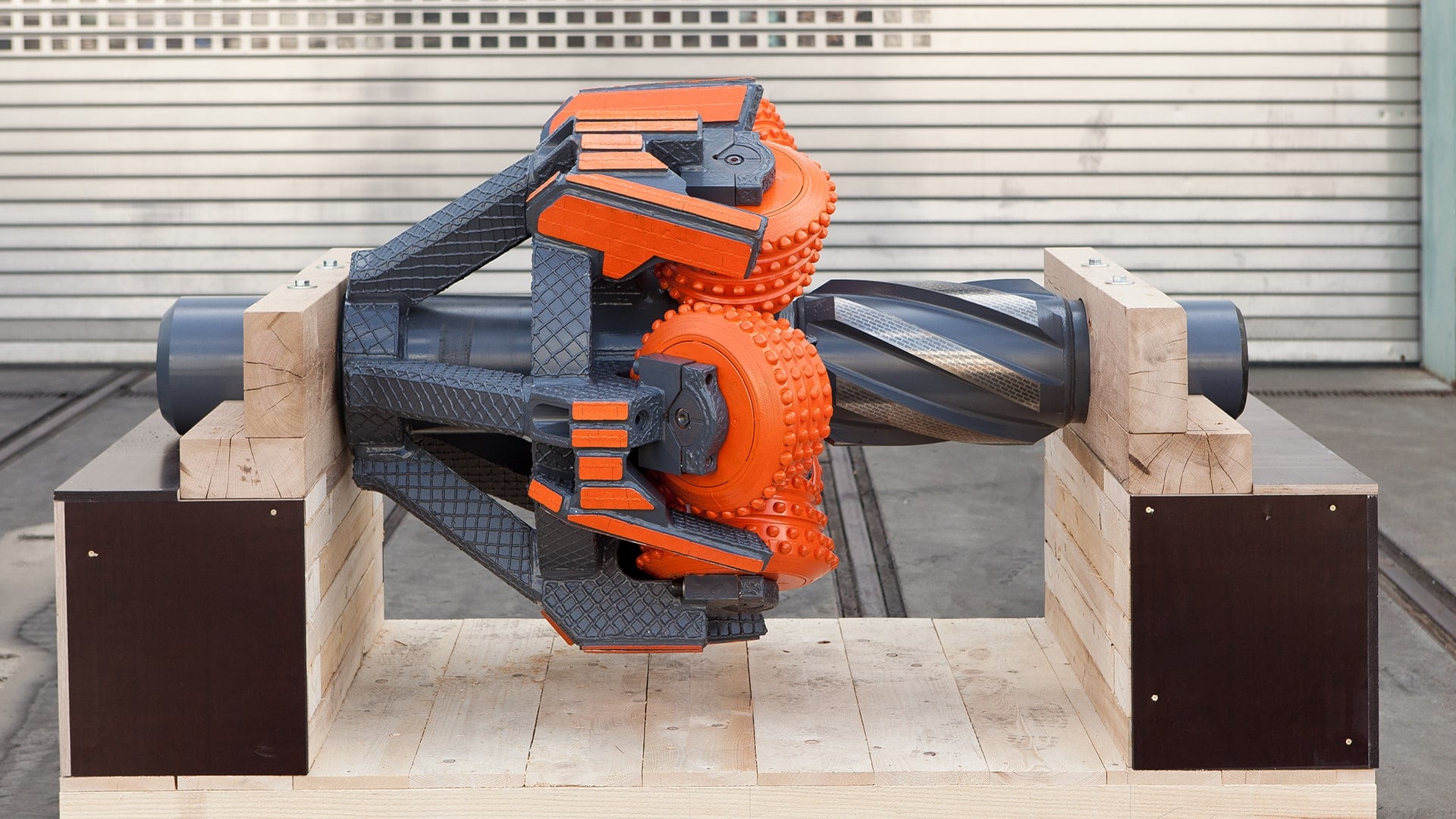

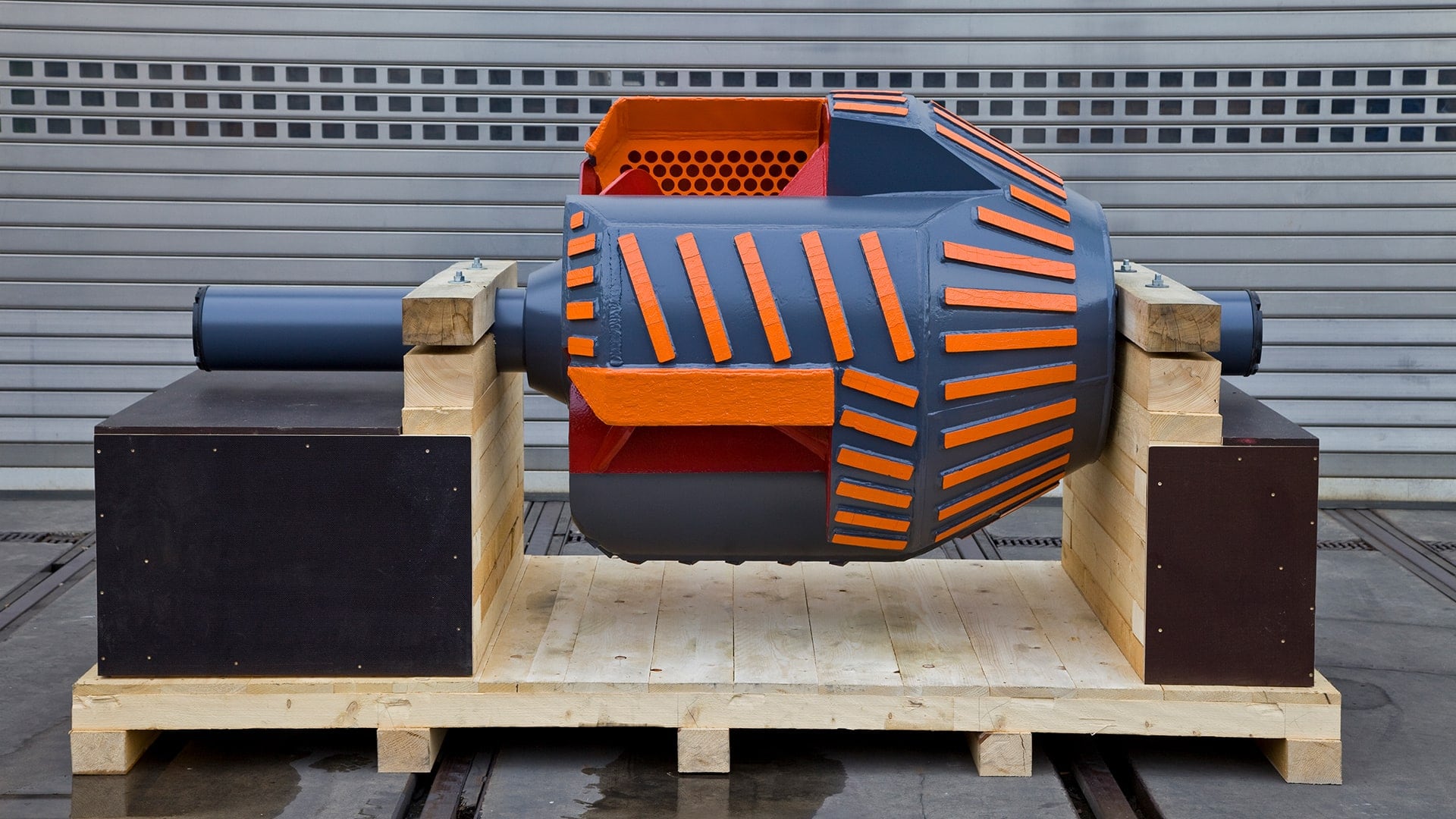

Weeper Sub: pilot drilling with optimized material flow

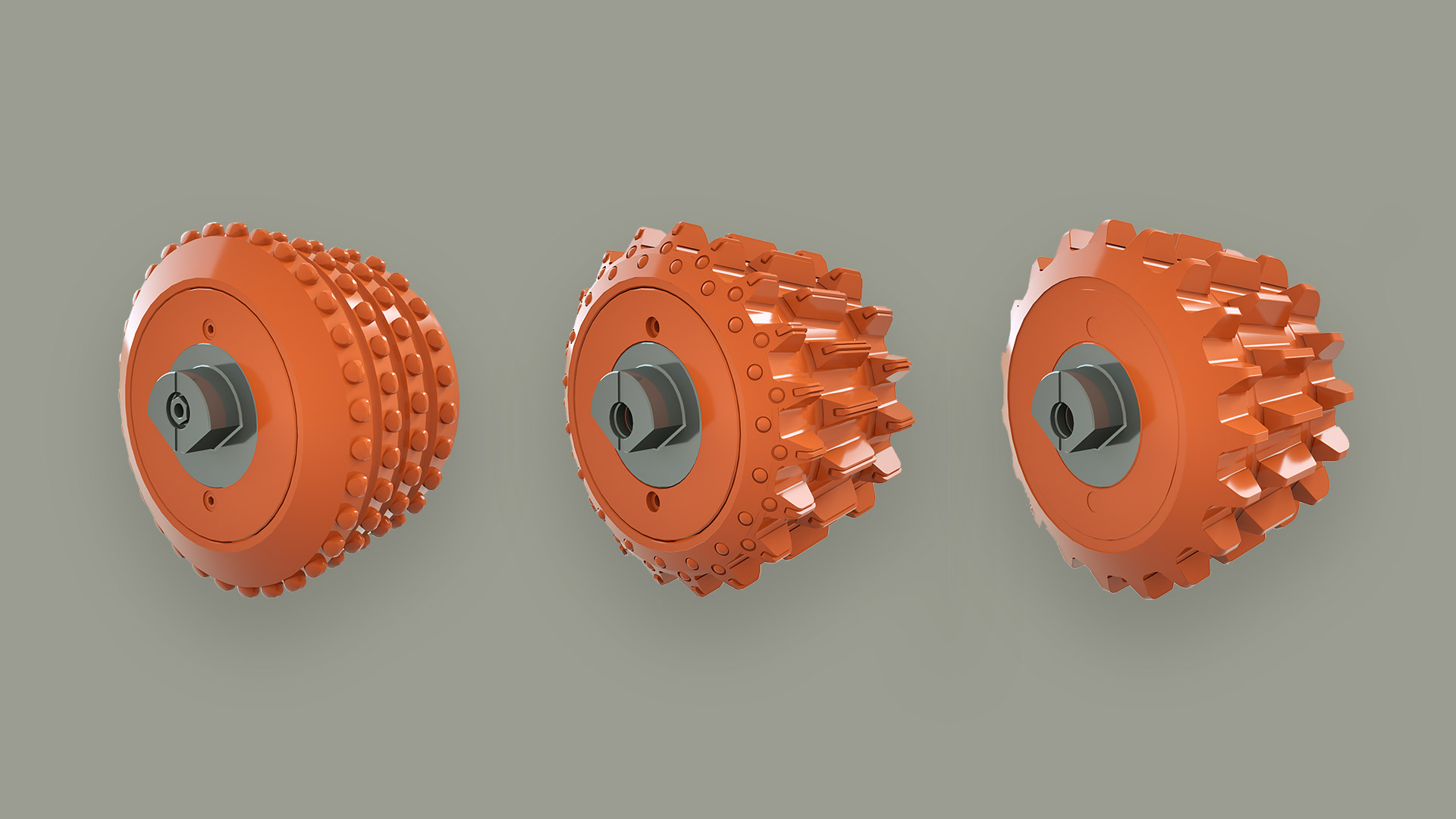

Weeper Subs significantly improve material flow when drilling HDD pilot holes. A nozzle removes part of the drilling fluid from the drill string and actively directs it into the flushing cycle in the annulus. This optimizes the material flow in the annulus and facilitates the removal of the sedimented drillings. The process is supported by the eccentric screw shape of the Weeper Sub. A clean pilot borehole without major deposits is the result.

Using multiple Weeper Subs gradually increases the volume flow in the borehole. The required amount of flushing fluid, on the other hand, decreases in the direction of the drill bit. This reduces the pressure level in the annulus and, in particular, the maximum pressure on the drill bit. The more balanced pressure level in the flushing cycle reduces the risk of frac-outs typical of the process.