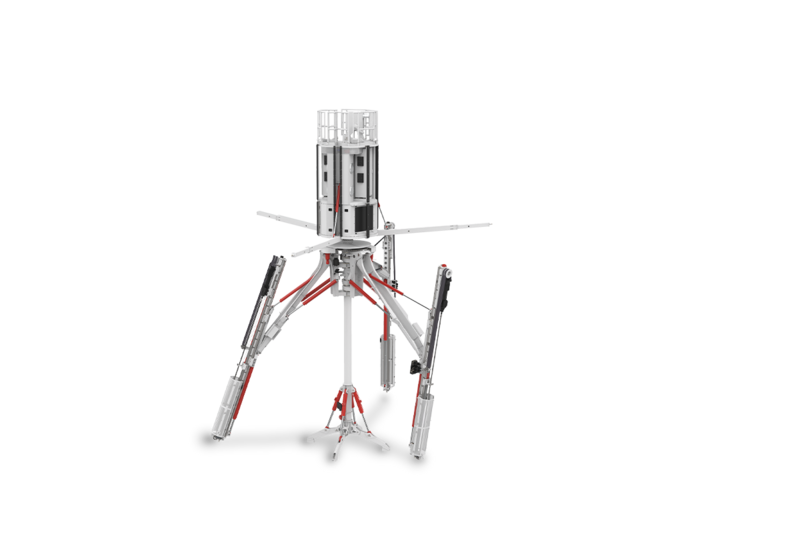

For the conventional construction of shafts in hard rock Herrenknecht has developed the new Shaft Drilling Jumbo, relying on proven mechanized underground technology. The modular jumbos are constructed in line with specific customer needs and can be used for shaft diameters of up to 12 meters. The optimized cycle times in the shaft lead to process acceleration, an increase in cost efficiency and at the same time to a reduction of potential hazards for the personnel.

Optimized technology based on proven Herrenknecht solutions

Herrenknecht has been using customized drilling rigs for rock support or geological exploration in tunnel boring machines of all diameter ranges for more than 30 years. The many years of experience with these drilling rigs were incorporated into the development of the Shaft Drilling Jumbos. The goal from the beginning was to achieve improved performances connected with high work safety for the machine personnel. These prerequisites could be implemented successfully thanks to special adaptations for vertical shaft sinking operations.

The Shaft Drilling Jumbo is used in projects where other methods are reaching their technical or economic limits. Each machine is designed to suit several excavation diameters and drilling patterns as well as specific project requirement like preliminary bolting operations and cover grouting operations.

High sinking performance, high work safety

In a first step, the system is sunk into the shaft and braced. An alternative design allows to chair it into the shaft galloways / stages. The subsequent drilling cycle is carried out using remote controls or automatically and with independent drilling all booms. This minimizes down-time and increases the drilling performance and work safety. Once a drilling cycle has been completed, the Shaft Drilling Jumbo is folded together and lifted up to the surface with a winch. Then the blasting cycle follows. The loosened material is transported either up to the surface in buckets or mucked down to the lower level through a pilot shaft. Following that, primary rock support using rock bolts, shotcrete or steel arches can be carried out from an independent working platform. At the same time, the Shaft Drilling Jumbo is already excavating the next drill pattern. In this way, 3-8 meters of shaft can be achieved per work day.

Functional principle

The Herrenknecht Shaft Drilling Jumbo is specifically designed according to customer requirements. The technology allows for rapid conventional shaft construction in hard rock with high occupational safety for the drilling crew. It can be used for a variety of applications both in mining and civil underground construction.

Still got questions?

We are ready!