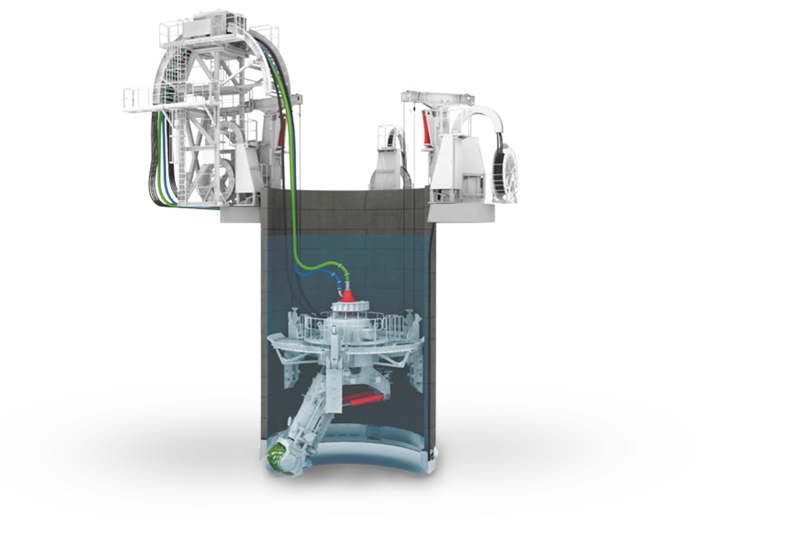

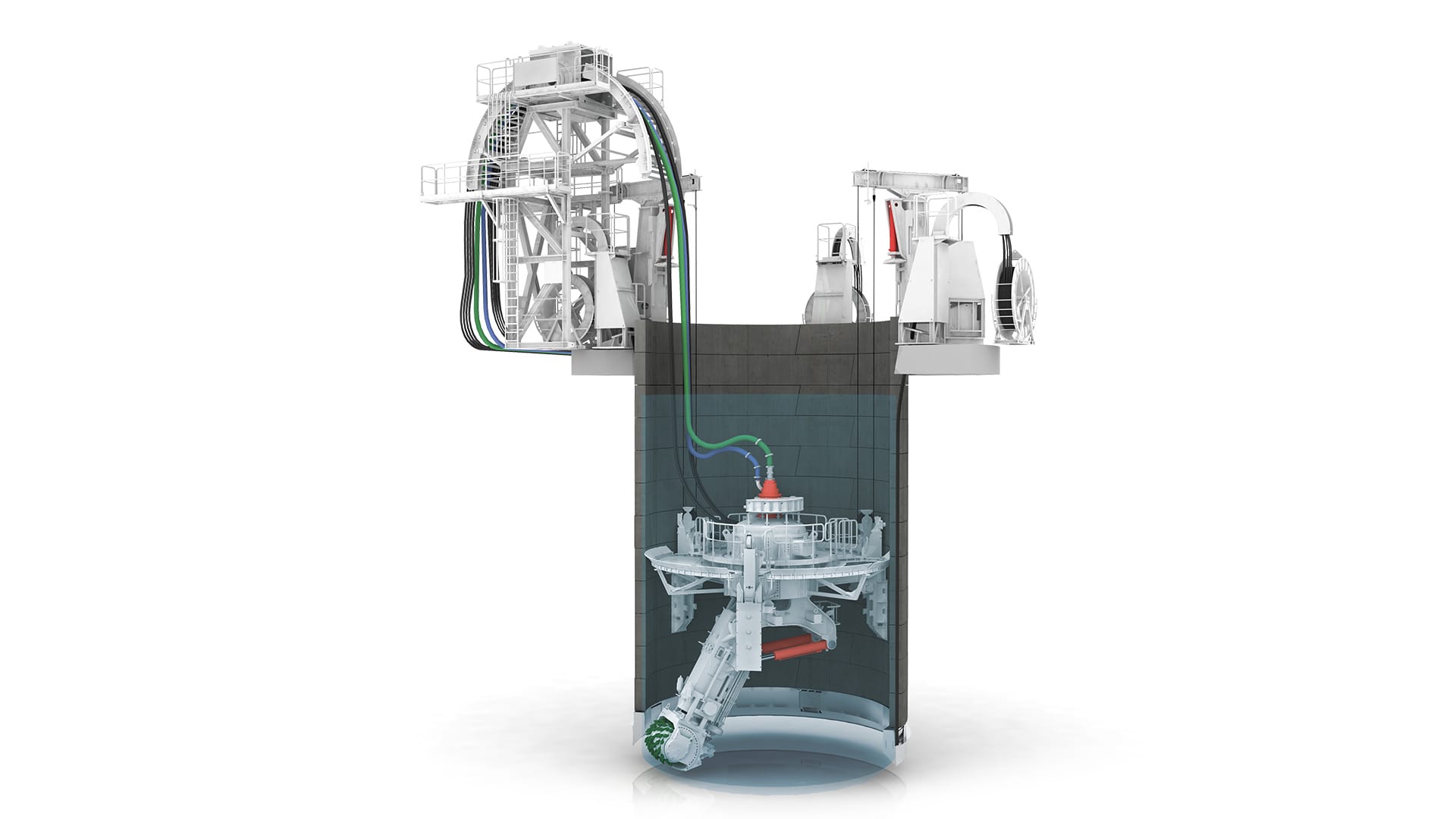

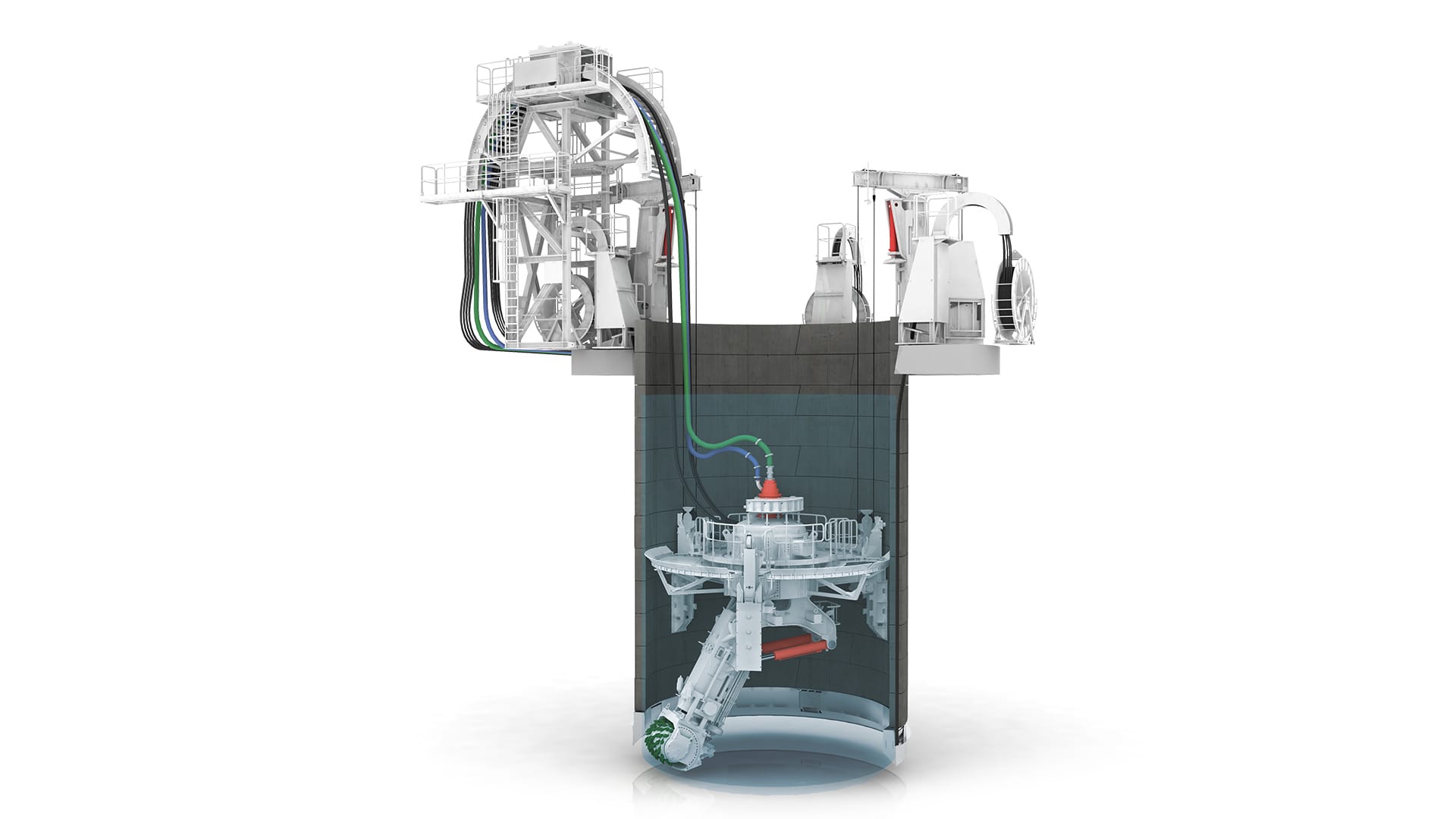

Operating principle at a glance:

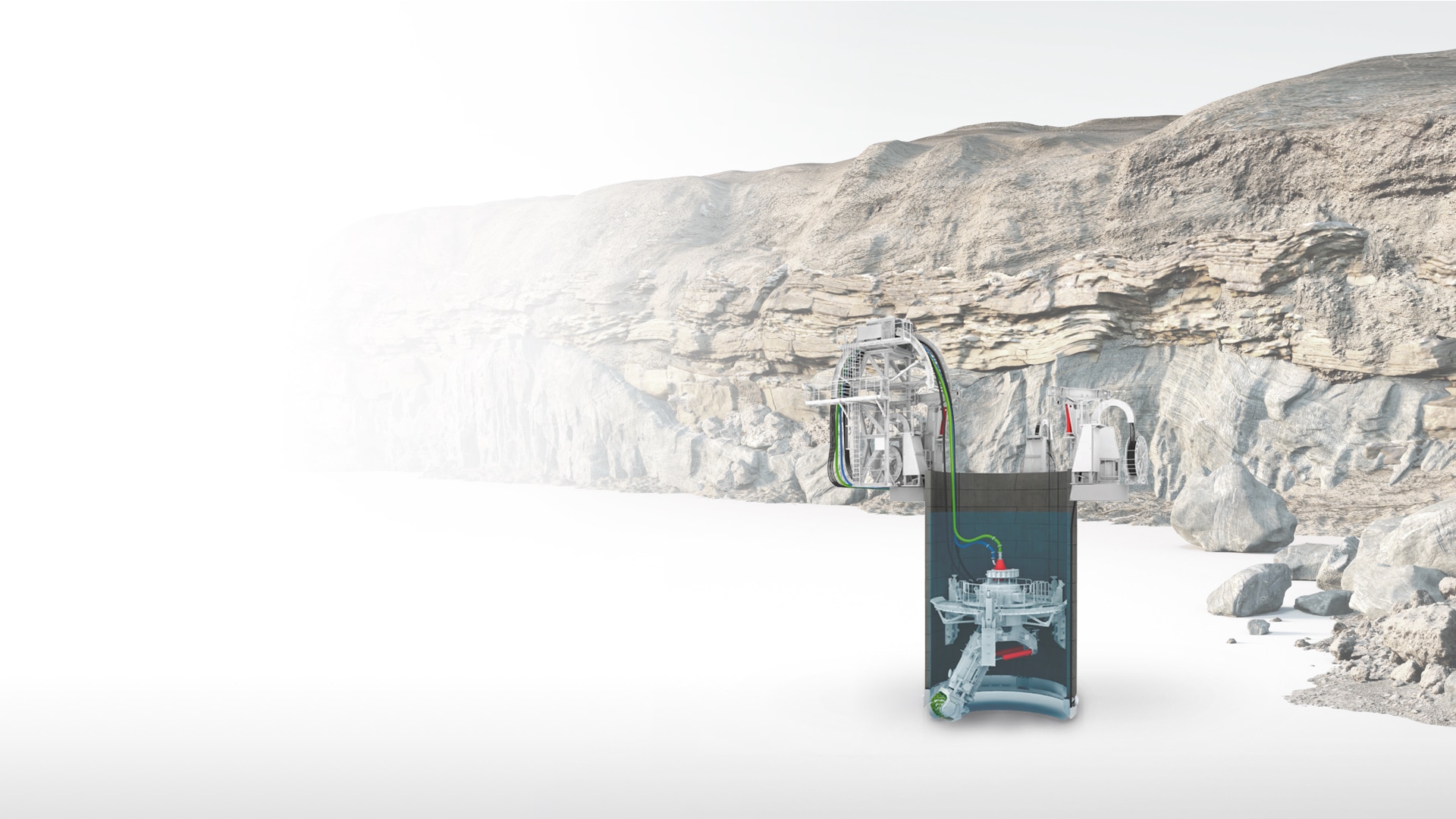

Vertical Shaft Sinking Machines (VSM) in operation

For quick and reliable construction of vertical shafts, Herrenknecht developed its VSM (Vertical Shaft Sinking Machine) technology, today an established product on the market. This unique mechanized shaft sinking equipment shows its strengths particularly below groundwater. In general, it can be used in soft and stable soils with compression strengths of up to 80 megapascal.

Excavation and shaft construction in one step

Every Herrenknecht Shaft Sinking Machine consists of two main components – the shaft boring machine and the lowering units. The shaft boring machine is lowered into the launch shaft structure and attached firmly to the shaft with its three machine arms. A rotating cutting drum equipped with chisel tools is attached to a telescopic boom. This roadheader excavates and breaks the soil at the base of the shaft. The roadheader is telescopic, and can swivel up and down or rotate. Hence, the entire cross-section of the shaft plus an overcut can be excavated gradually. The excavated material is removed hydraulically through a submersible pump and transported to the separation plant on the surface. The lower concrete ring of the shaft structure, also referred to as the shaft’s cutting edge, is beveled and therefore cuts into the surrounding soil underneath. In addition, the overcut of the roadheader-like telescopic boom and cutting drum below the shaft’s cutting edge in combination with the bentonite lubrication in the annular gap reduce the frictional forces between the shaft wall and the surrounding soil. On the surface, 3 to 4 lowering units with hydraulic cylinders are attached firmly to the ring-shaped concrete foundation around the shaft. They are attached to the lower concrete base ring of the shaft structure by steel cables. In this way, the entire shaft structure can be held and lowered in a controlled manner during excavation. Ring building takes place simultaneously on the surface using prefabricated concrete segments. The simultaneous working processes (excavation, removal of excavated material, shaft construction, and lowering of the shaft structure) make it possible for VSM technology to achieve high advance rates of up to 5 meters per shift.

Functional principle

Step by step to a finished shaft

The entire shaft is flooded with slurry water at the start of excavation. The slurry water circuit required to transport the excavated material can be primed. This also means that lowering the groundwater table is not necessary. The separation plant removes the slurry water from the excavated material and recycles it back into the shaft pool. The shaft structure is lowered continuously while ring building takes place at the surface. When the desired depth has been reached, the machine is recovered. Subsequently, the shaft bottom is sealed by an underwater concrete plug and the annular gap is filled up with grout, creating a frictional support locking the shaft in place. Once the slurry water is pumped off, the shaft is ready for further use.

A cutting drum equipped with excavation tools loosens the soil on the shaft bottom

Hydraulic removal of the excavated material to the surface using a submersible pump

Controlled lowering of the shaft structure using the lowering units

Shaft construction at the surface with pre-cast reinforced concrete segments or in-situ concrete casting

Everything under control from above

All operational processes are controlled and monitored from the surface. In addition to the separation plant, lowering units and recovery winches, the jobsite equipment includes a control container and power supply units. All information available about the excavation is collected and visualized in the control container. There, the operator has a full overview of the situation at hand and can respond accordingly at all times. After completing excavation or when changing excavation tools, the shaft boring machine is retrieved using the recovery winches. The advantages of the modular design of the overall system become particularly apparent in inner-city projects. The equipment can be arranged as needed. For example, the separation plant can be installed in a street next to the jobsite if there is not enough space for it next to the shaft.

Wide range of applications

Shafts constructed using Herrenknecht VSM technology have a wide range of applications. With diameters ranging from 4.5 to 12 meters, they can be used as launch and reception shafts for tunnelling operations, access and ventilation shafts for traffic tunnels, or service and access points for all kinds of underground structures and buildings. Furthermore, special solutions such as inner-city, underground parking shafts (underground parking towers) or exploration and ventilation shafts for mining extend the range of applications of these flexible machines. Customized solutions for even larger diameters of up to 18 meters are possible. The innovative VSM technology has demonstrated its advantages in several projects. It allows for safe, fast, and environmentally-friendly production of vertical shafts of all kinds. Its advantages become particularly clear in difficult geologies beneath groundwater and where space on the jobsite is constrained.

Still got questions?

We are ready!