Your exclusive customer link to the digital world of tunnelling

Single Shield TBMs in operation

Single Shield TBMs are the ideal machine type for tunnelling through rock and other stable, non-groundwater-bearing soils. Due to the typical tunnelling methods with segmental lining or pipe jacking, high tunnelling performances can also be achieved in rock formations with low stand-up times.

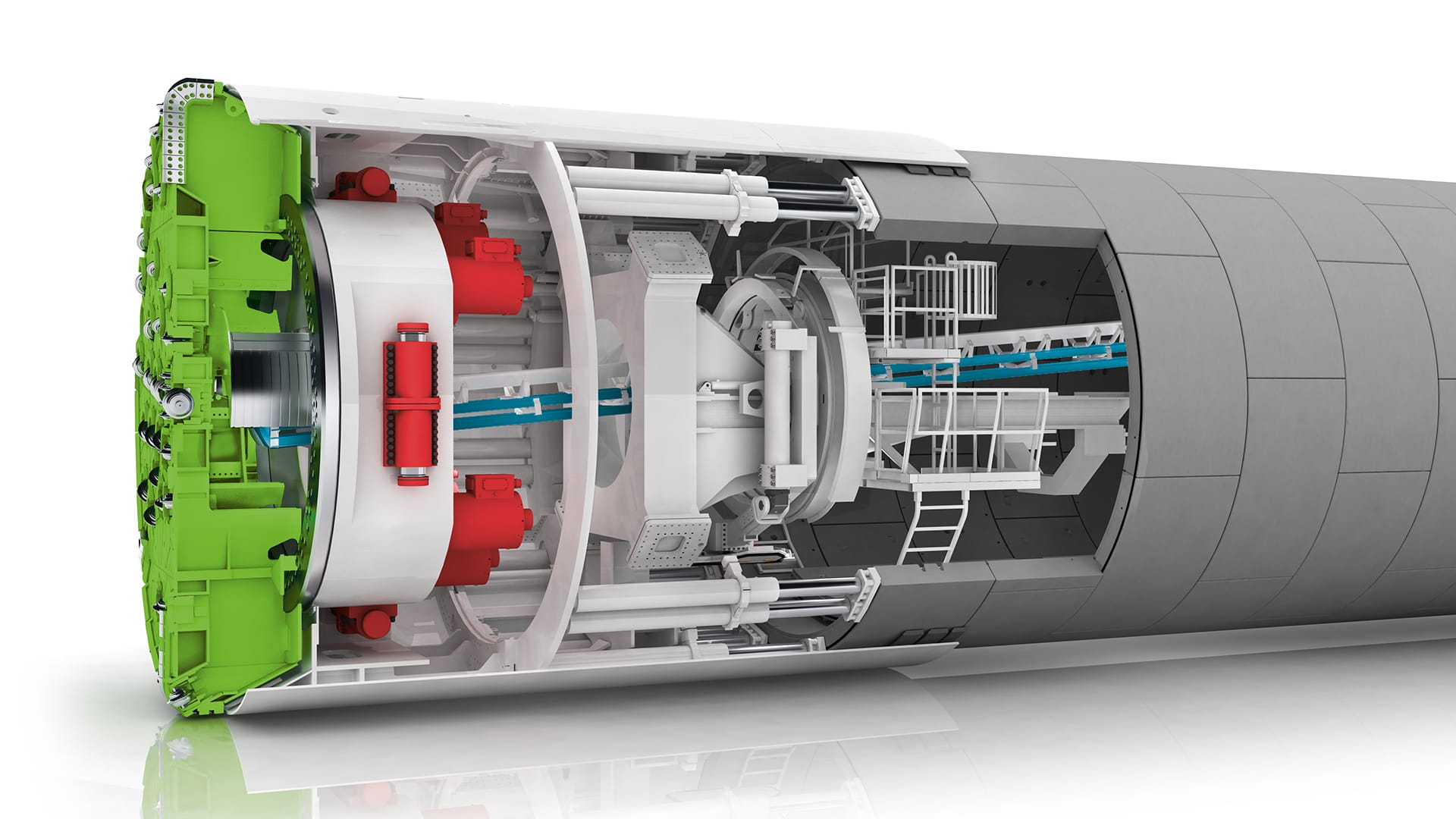

Advancing with power

When tunnelling with a Single Shield TBM, a rotating cutterhead equipped with disc cutters is pressed against the tunnel face with a pressure of up to 32 tonnes per disc. Due to the rolling movement of the discs, single pieces – so-called chips – are broken out of the rock. Water jets can cool the cutting tools and reduce dust formation. Buckets installed at the cutterhead take up the excavated material. Thanks to gravity, it slides to the center of the machine through integrated muck chutes while the cutterhead rotates and then falls through the funnel-shaped muck ring onto the machine belt. At the end of the machine belt, the rock chips are passed on to belt conveyors or transport vehicles and removed from the tunnel.

Precise control, easy tool replacement

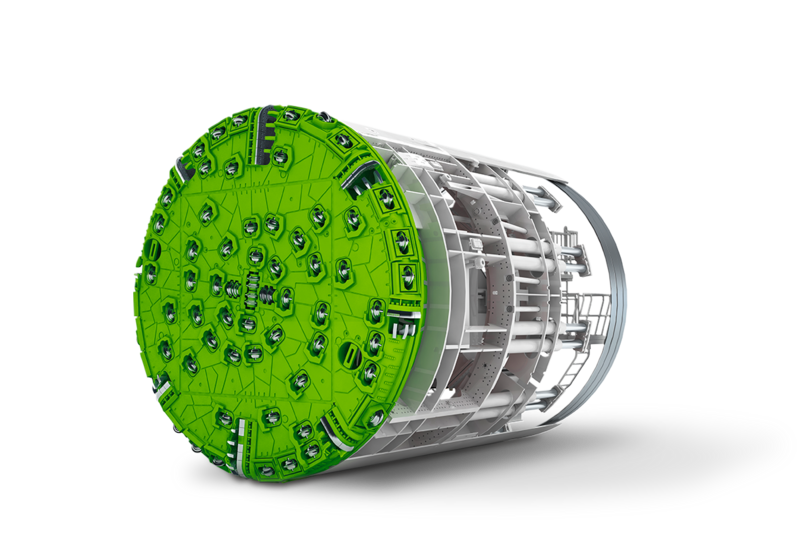

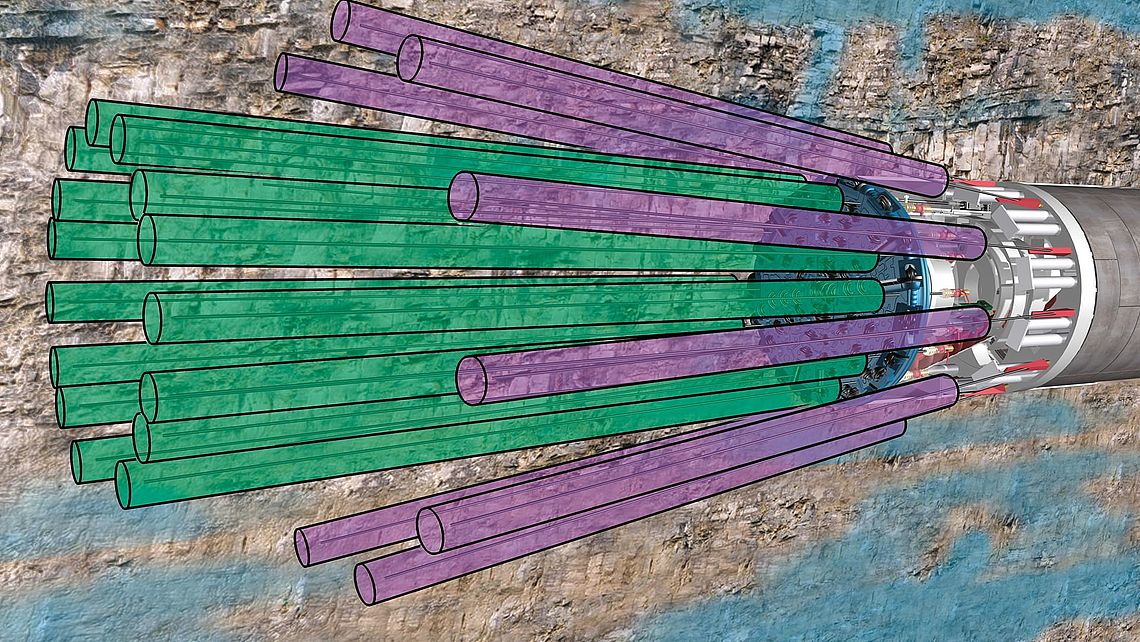

Shielded Hard Rock TBMs have an excavation diameter which is larger than the shield skin. In addition, the excavation axis of the cutterhead is slightly higher than the machine axis. This overcut makes it possible to control the machine and protects it against jamming in the rock. Hydraulic stabilizer plates integrated into the shield can be braced in the tunnel already excavated. This reduces vibrations and stabilizes the machine during the boring process.

To control the machine, either firmly installed drives with steering cylinders or movable drives with articulation bearings or torque box cylinders and additional longitudinal displacement cylinders are used. This allows for tunnelling with very small radii. With all drive types, the cutterhead can be pulled back allowing direct access to the tunnel face. This means that the disc cutters worn out in the excavation process can be easily replaced. Another special feature applies to the Single Shield TBM in pipe jacking: the cutterhead can be rotated in both directions which counters the risk of the machine rolling.

Operating principle at a glance:

Disc cutters break chips from the tunnel face by applying high contact pressure

Buckets, muck chutes, and muck ring provide for an efficient removal of the excavated material onto a center belt conveyor

Hydraulic thrust cylinders in the shield or a jacking frame in the launch shaft push the machine forward

Segmental lining or pipe jacking

Fast and safe

The Single Shield TBM is secured in the ground using segments or pipe jacking. This minimizes the dependency between tunnelling and tunnel lining in brittle rock formations or rock with low strength. The machine is protected at all times, additional measures to secure the rock are usually not necessary and corresponding delays in tunnelling can be avoided. In accessible machines, soil conditioning enhances the geological range of application. Water inflows can thus be reduced to a controllable measure. For this purpose, an injection body is built up in front of the tunnel face using injection drills through the cutterhead and the shield. Drainage systems drain the entering water in a controlled manner.

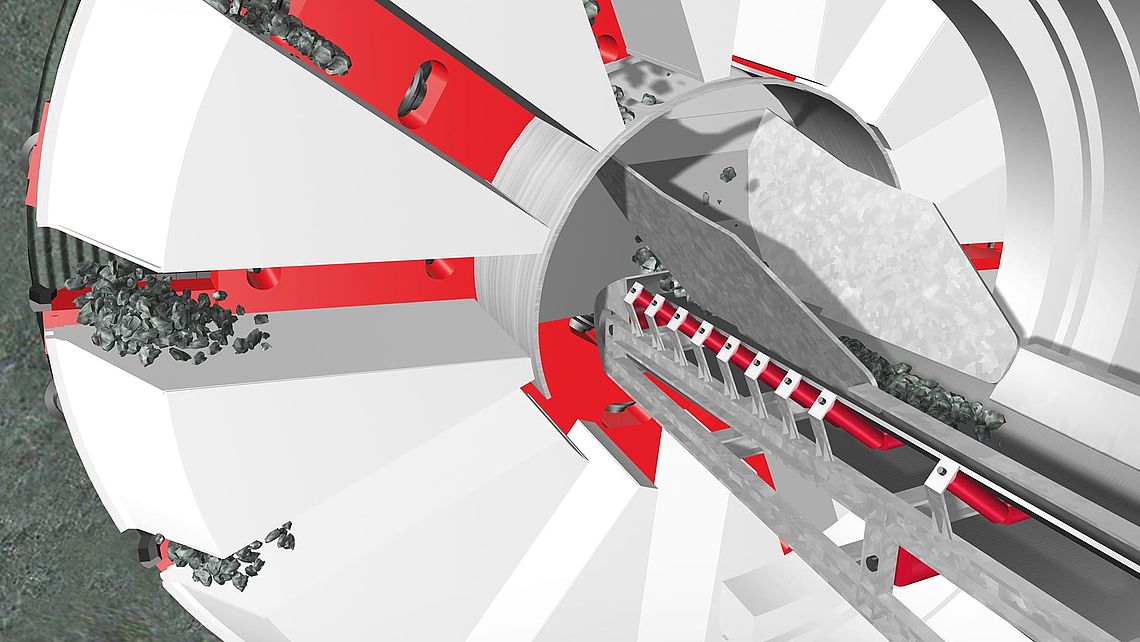

With know-how against wear and tear

Tunnelling through hard rock with strengths of up to 250 megapascal at some places requires enormous forces. The disc cutters can only break the hard rock if a very high contact pressure is applied. If chips are big, this is proof of fast tunnelling with optimum pressure force and low wear and tear of the disc cutters. If the contact pressure is too low, the rock is not crushed ideally and the discs wear out faster. With smaller excavation diameters and restricted space for the cutting tools, in particular, the cutterhead design, torque and contact pressure must be coordinated exactly, taking into consideration the expected geology. The optimum arrangement of the disc cutters on the cutterhead and drives with a strong torque and high contact pressure are the most important factors in ensuring fast tunnelling through hard rock with as little wear and tear as possible. Building on numerous project references, Herrenknecht can rely on a unique wealth of experience and is able to develop project-specific solutions.

All-rounder in rock

The simple tunnelling concept in combination with a wide range of applications makes the Single Shield TBMs all-rounders for tunnelling in rock formations. In many cases, they are the optimum solution for tunnelling with very high rock strengths both in pipe jacking and segmental lining. In addition, single shields can be used successfully in groundwater-bearing rock formations using soil conditioning.

Still got questions?

We are ready!