Your exclusive customer link to the digital world of tunnelling

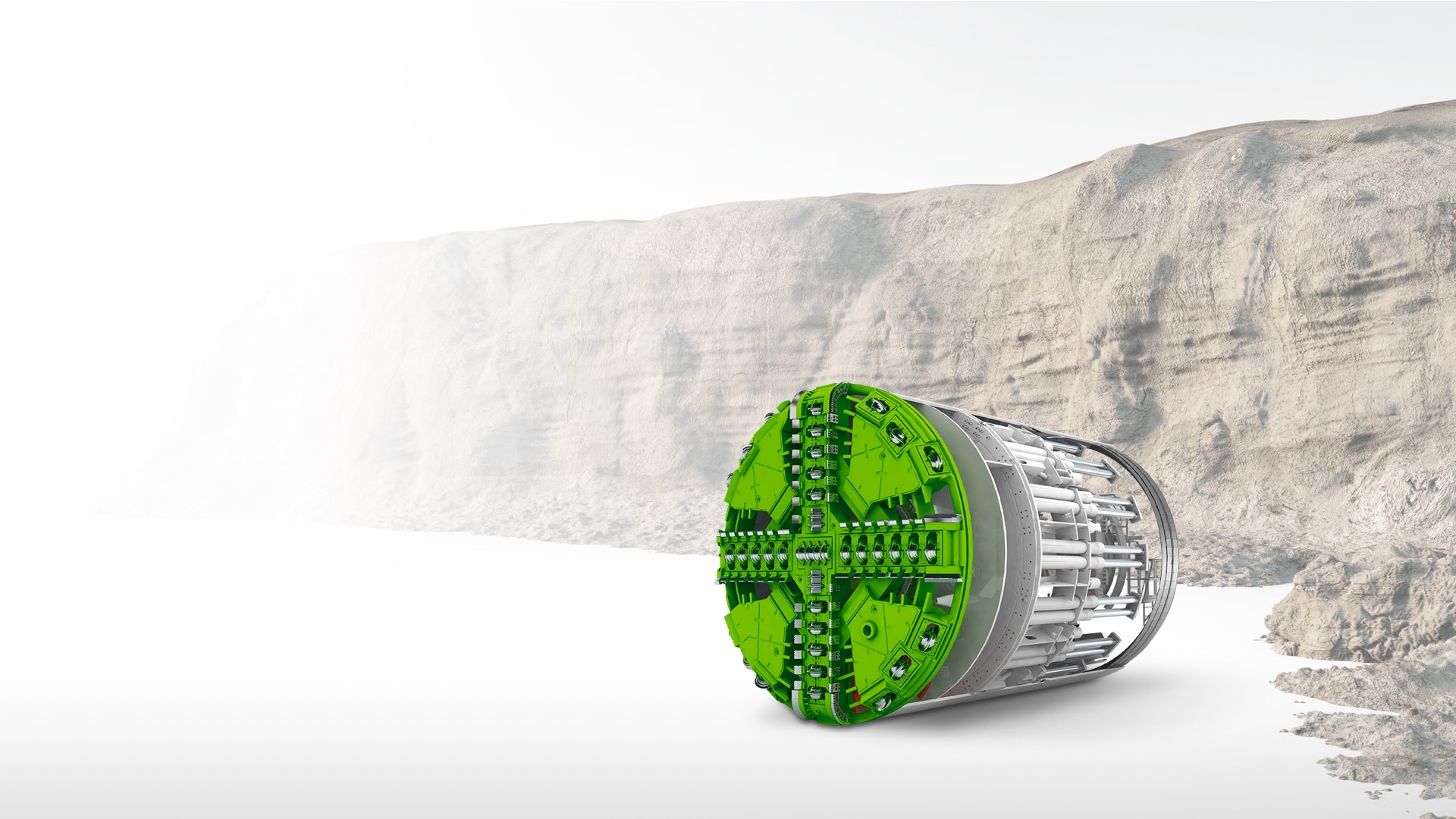

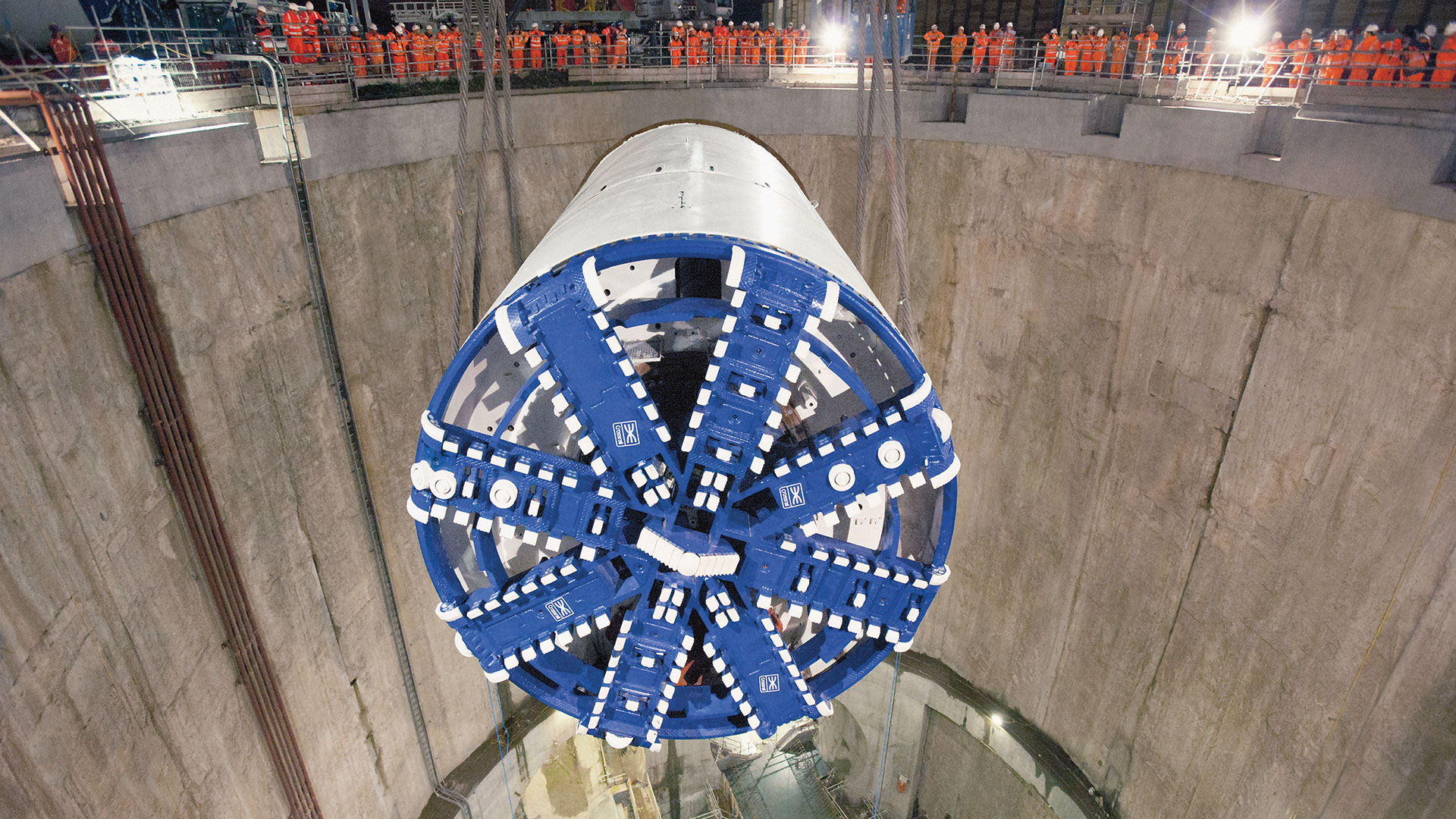

EPB Shields in operation

For soft, cohesive soils tunnel boring machines with earth pressure support are a preferred option. So called Earth Pressure Balance Shields (EPB) turn the excavated material into a soil paste that is used as pliable, plastic support medium. This makes it possible to balance the pressure conditions at the tunnel face, avoids uncontrolled inflow of soil into the machine and creates the conditions for rapid tunnelling with minimum settlement.

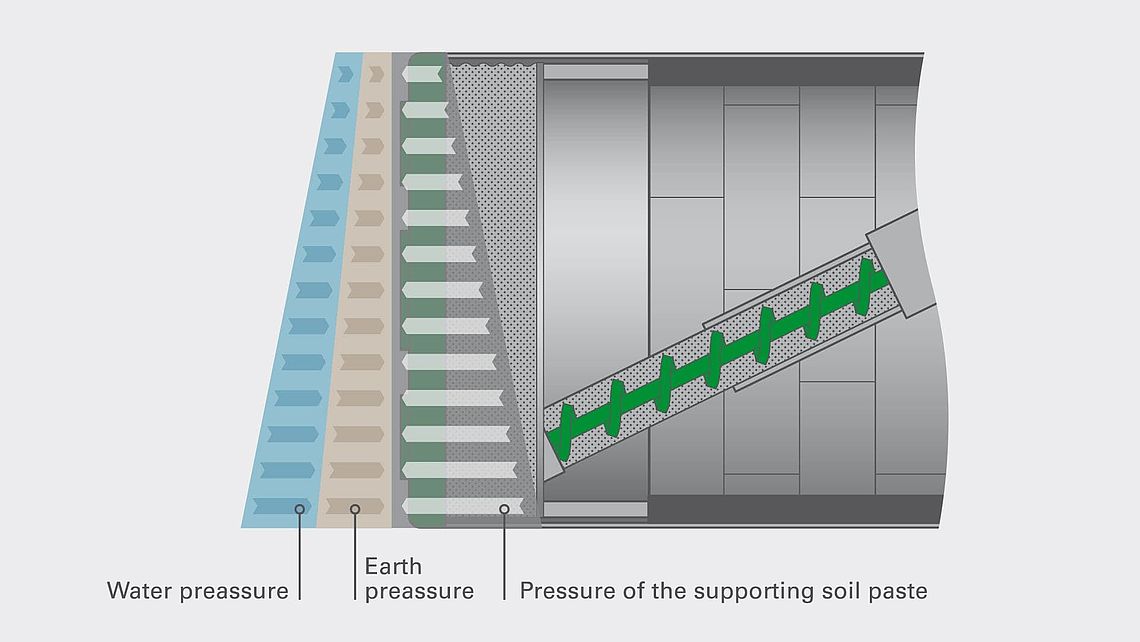

Stability through face support pressure

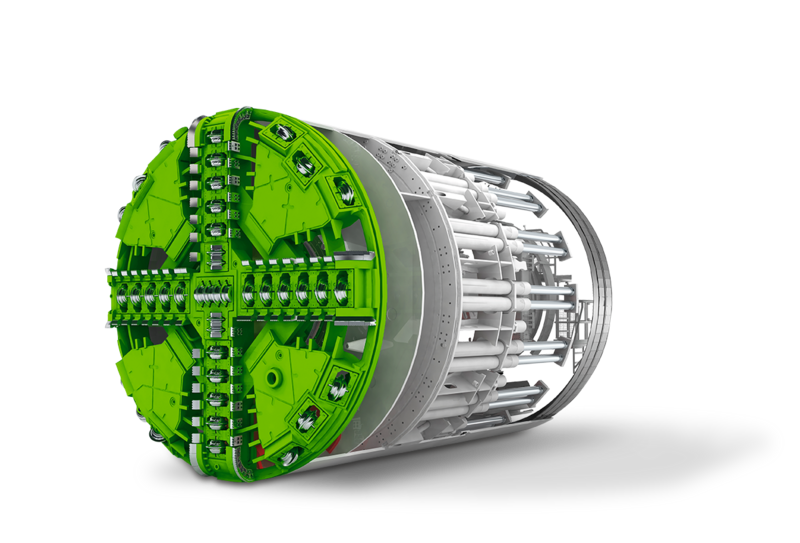

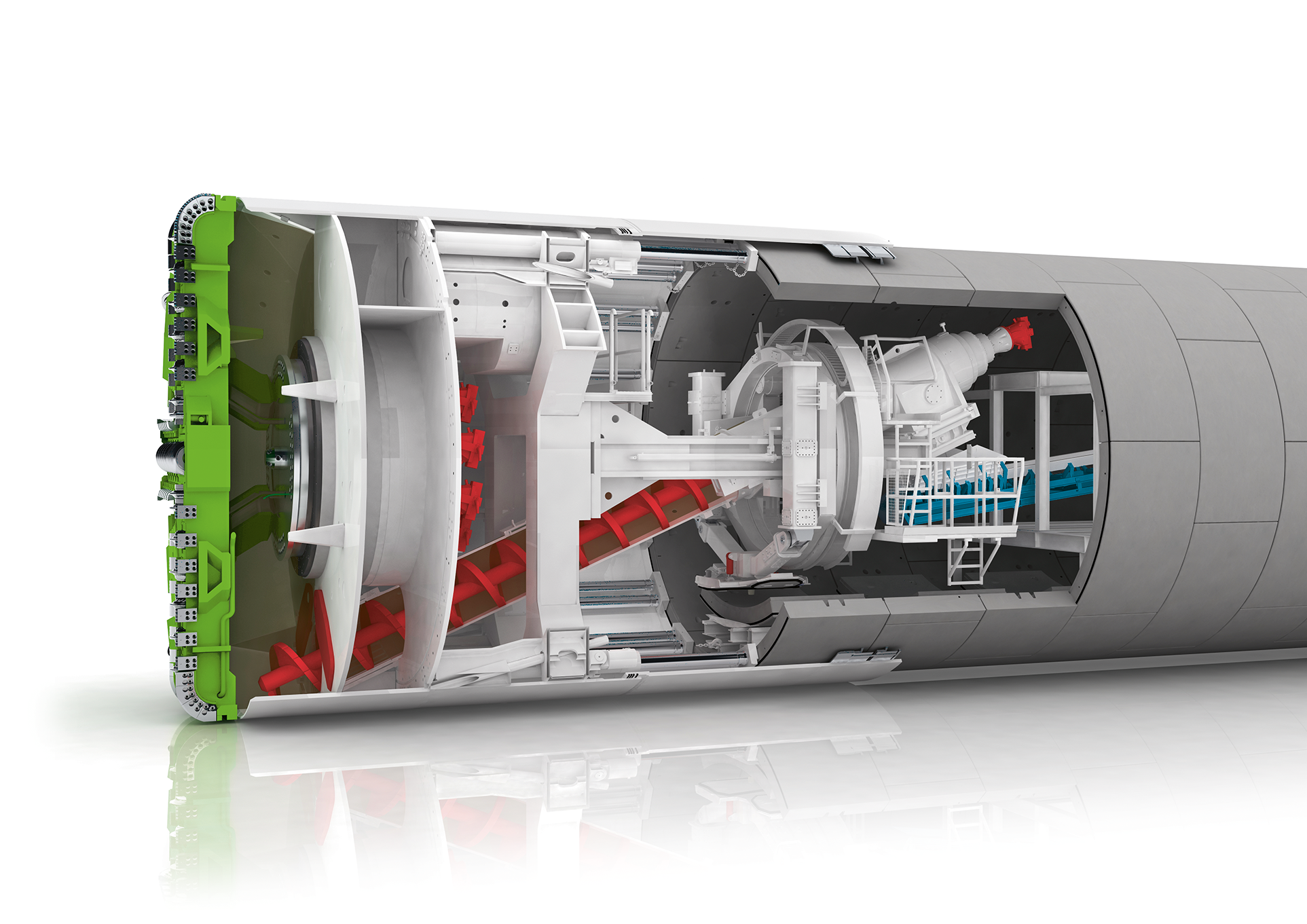

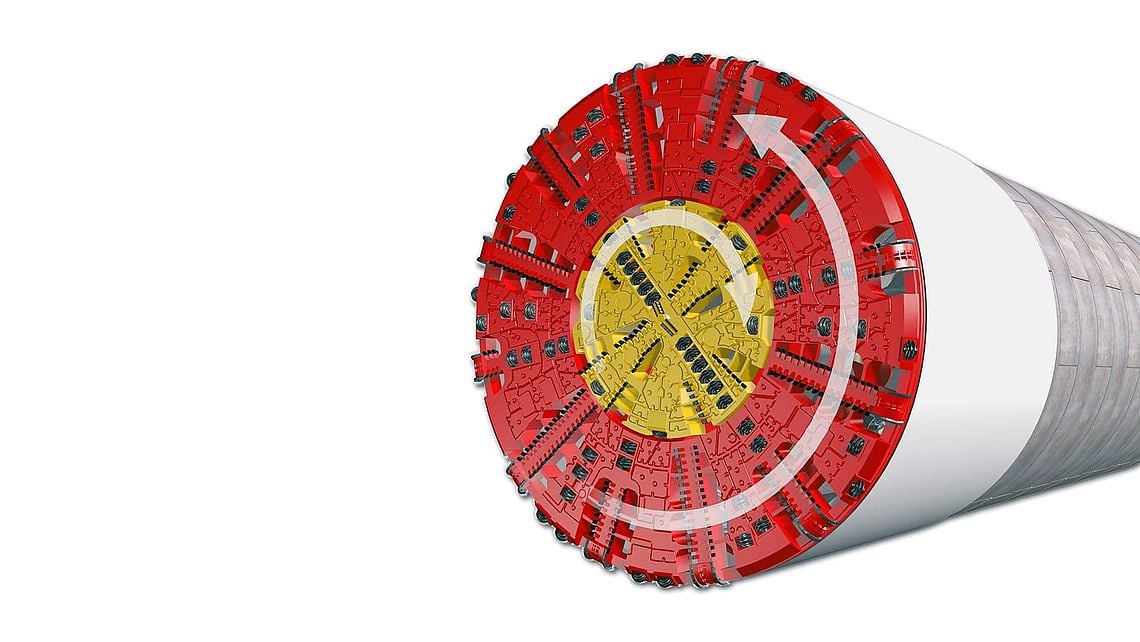

The special feature of Earth Pressure Balance Shields is that they use the excavated soil directly as support medium. This method is the first choice in cohesive soils with high clay and silt contents and low water permeability. A rotating cutting wheel equipped with tools is pressed onto the tunnel face and excavates the material. The soil enters the excavation chamber through openings, where it mixes with the soil paste already there. Mixing arms on the cutting wheel and bulkhead mix the paste until it has the required texture. The bulkhead transfers the pressure of the thrust cylinders to the pliable soil paste. When the pressure of the soil paste in the excavation chamber equals the pressure of the surrounding soil and groundwater, the necessary balance has been achieved.

Screw conveyor speed and TBM advance rate regulate the pressure conditions

A screw conveyor transports the excavated material from the base of the excavation chamber onto a belt conveyor. The interaction between the screw conveyor’s throughput and the TBM’s advance rate ensure that the support pressure of the soil paste can be controlled precisely. The balance in the excavation chamber is continuously monitored using earth pressure sensors. In this way, the TBM operator is able to fine-tune all tunnelling parameters to each other even under changing geological conditions, allowing for high advance rates and minimizing the risk of heave or settlement at the surface.

Operating principle at a glance:

Cutting knives and disc cutters remove the soil

Pliable, plastic soil produces active support pressure in the excavation chamber

A screw conveyor transports the excavated material to the logistics systems at the back

Hydraulic thrust cylinders in the shield or a jacking frame in the launch shaft push the machine forward

Segmental lining or pipe jacking

Wider application range through perfect soil conditioning

Not all ground conditions have ideal characteristics for EPB tunnelling in their natural state. However, the application range of this method can be enhanced tremendously by soil conditioning. This means changing the plasticity, texture and water permeability of the soil by injecting various conditioning materials such as water, bentonite or foam. This allows EPB Shields to achieve good advance rates even in heterogeneous soils containing gravel, sand or water, or in unstable geological conditions.

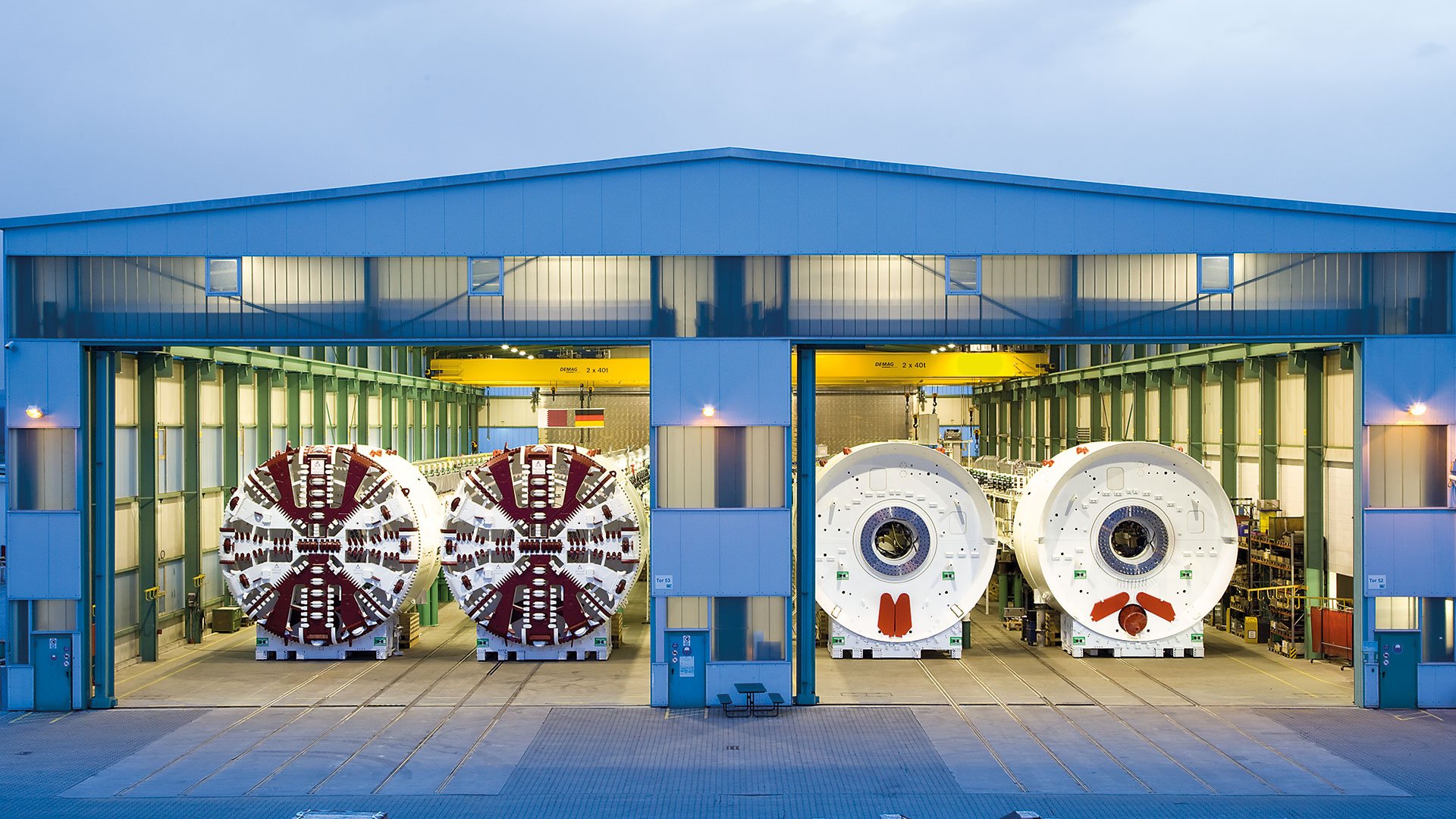

New developments for large dimensions

Herrenknecht developed a new cutting wheel concept to master excavation diameters of more than 10 meters in highly abrasive ground. These are EPB Shields with two cutting wheels mounted on the same operating plane, which can rotate independently of each other in both directions. The high torque can thus be introduced into the soil gradually, beginning with the center cutting wheel as it “rushes ahead”. Together with soil conditioning, this reduces wear and tear of the excavation tools. Two large screw conveyors in the lower shield section move the large quantity of excavated material from the outer sections of the cutting wheel backwards. A smaller screw conveyor in the center removes the excavated material from the inner cutting wheel.

Herrenknecht EPB Shields successfully accomplished breakthrough in more than 500 projects worldwide.

Technological innovations for special requirements

The special advantage of Earth Pressure Balance Shields is their extreme flexibility. A range of developments at Herrenknecht have greatly enhanced the application range of this method. With conventional screw conveyors, it is not possible to build up a sufficient soil plug to maintain the support pressure in cohesive soils with increased water pressure. Such soils can, however, be controlled safely using muck pumps. The piston pumps completely seal the system behind the screw. This allows the screw, thus maintaining the pressure level at the tunnel face.

In incohesive soils with high groundwater content, the slurryfier box developed by Herrenknecht can be installed subsequently. This special innovation connects the exit port of the screw conveyor with the slurry circuit. The excavated material is then transported hydraulically and the EPB Shield can continue to work in slurry mode.

The allrounder principle EPB

The concept of earth pressure support makes EPB technology an all-rounder for soft, cohesive soils of all kinds. In addition, the geological scope of application can be enhanced using soil conditioning and the technological innovations from Herrenknecht. This applies to both small excavation diameters in pipe jacking and large and even very large diameters with segmental lining.

Still got questions?

We are ready!